Picture this: you walk into a high-end boutique, and your eyes are immediately drawn to a stunning glass etching displayed on a shelf. The intricate patterns and detailed designs captivate you, leaving you in awe of the craftsmanship. Have you ever wondered how these masterpieces are created? The secret lies in optimizing designs for laser cutting for glass etching.

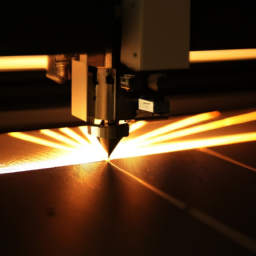

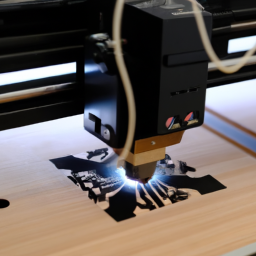

Laser cutting technology has revolutionized the art of glass etching, offering a multitude of benefits that enhance precision, efficiency, and cost-effectiveness. By harnessing the power of laser cutting, artisans can create intricate and detailed patterns that were once unimaginable. The possibilities for design are expanded, allowing for endless creativity and innovation.

But it’s not just about aesthetics. Optimizing designs for laser cutting also improves the quality and professionalism of the final product. With greater precision and accuracy, every etching is flawless, leaving a lasting impression on anyone who lays eyes on it.

In this article, we will dive deeper into the benefits of optimizing designs for laser cutting for glass etching. From enhanced precision to expanded design possibilities, you will discover how this cutting-edge technology is shaping the world of glass etching. Get ready to be inspired and amazed by the endless possibilities that await you.

Key Takeaways

- Laser cutting technology revolutionizes glass etching, offering enhanced precision and accuracy.

- Optimizing designs for laser cutting improves the quality and professionalism of glass etching.

- Laser cutting technology ensures greater efficiency, saving time and reducing waste in the glass etching process.

- Laser cutting for glass etching is cost-effective, reducing wastage, increasing productivity, and allowing for artistic customization and expanded design possibilities.

Enhanced Precision and Accuracy

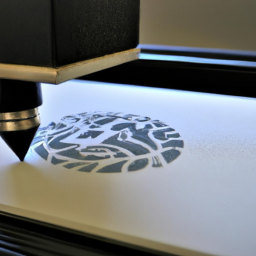

When you optimize your designs for laser cutting, you’ll be amazed at the enhanced precision and accuracy that can be achieved, giving your glass etchings a flawless and professional finish.

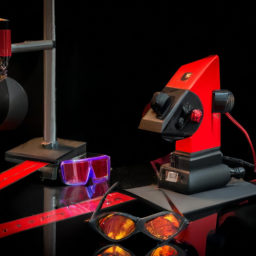

By utilizing laser cutting technology, you can ensure improved functionality in your designs. The laser’s high level of precision allows for intricate and detailed etchings that would be difficult to achieve through traditional methods. Additionally, laser cutting offers increased customization options, as it can easily cut through various types and thicknesses of glass, allowing you to create unique and personalized designs.

This level of precision and customization sets your glass etchings apart and gives them a distinct edge. By optimizing your designs for laser cutting, you can achieve impeccable results and take your glass etching projects to the next level.

This enhanced precision and customization also leads to greater efficiency in the etching process, ensuring a seamless transition from design to finished product.

Greater Efficiency in the Etching Process

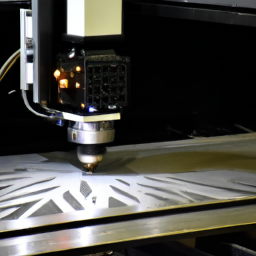

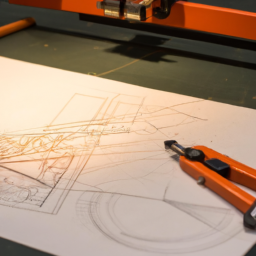

By streamlining the production process, laser-cutting for glass etching allows for a more seamless and time-saving experience. It offers significant benefits for both small-scale projects and large-scale productions. Here are three reasons why laser cutting is a game-changer in glass etching:

-

Precision: Laser cutting technology ensures precise and accurate cuts, resulting in intricate and detailed designs that were previously difficult to achieve by hand. This level of precision allows for more complex and stunning etchings.

-

Speed: Laser cutting significantly reduces the time required for glass etching. The laser beam can swiftly cut through the material, allowing for faster production without compromising quality.

-

Material Efficiency: Laser cutting minimizes material waste by optimizing the design layout. By precisely cutting the desired pattern, it maximizes the use of the glass sheet, reducing scrap and saving costs.

With these advantages, laser-cutting for glass etching proves to be not only efficient but also cost-effective in production.

Cost-Effectiveness in Production

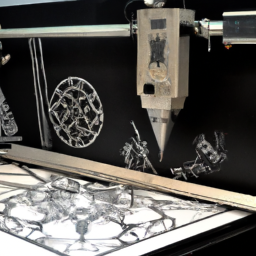

To save money in production, you can take advantage of the cost-effectiveness of laser-cutting for etching glass. Laser cutting allows for reduced wastage and increased productivity, leading to significant cost savings in the long run. By optimizing designs specifically for laser cutting, you can minimize material waste and maximize the number of pieces that can be cut from a single sheet of glass. This means you can produce more etched glass products with the same amount of raw materials, reducing your production costs. Additionally, laser cutting is a highly precise and efficient process, which helps to increase overall productivity and decrease production time. With the ability to create intricate and detailed patterns, laser-cutting for glass etching offers endless design possibilities.

Ability to Create Intricate and Detailed Patterns

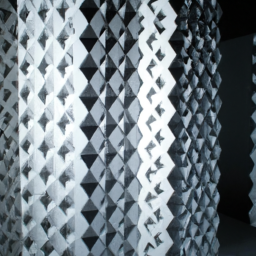

With laser cutting, you can achieve incredibly intricate and detailed patterns on glass, captivating customers with designs that are 10 times more intricate than traditional etching methods. The precision control offered by laser cutting allows for the creation of delicate lines and intricate shapes that were once impossible to achieve.

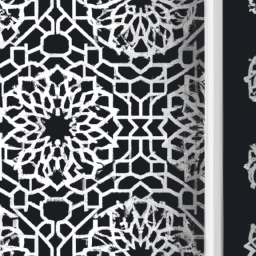

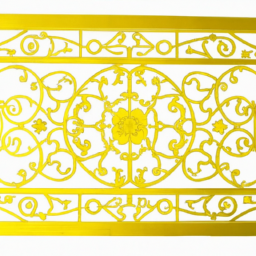

This technology enables artistic customization like never before, allowing you to bring your unique vision to life. The possibilities are endless with laser cutting for glass etching. Imagine creating stunning floral patterns with intricate petals and delicate stems. Picture intricate geometric designs with perfectly straight lines and sharp angles. Envision detailed portraits etched onto glass with every subtle feature captured flawlessly.

The ability to create such intricate and detailed patterns opens up a world of expanded design possibilities, taking glass etching to a whole new level.

Expanded Design Possibilities

Imagine the limitless creativity that awaits you as you explore the expanded design possibilities of laser cutting for glass etching. With design customization at your fingertips, you can create intricate and detailed patterns that were once impossible to achieve by hand.

The precision and accuracy of laser cutting allow for complex designs to be etched onto glass, resulting in unique aesthetics that are sure to captivate the eye. Whether you want to etch intricate floral patterns or intricate geometric shapes, laser cutting provides the flexibility to bring your vision to life with ease.

By embracing this technology, you can unlock a whole new world of design possibilities that will elevate your glass etching projects to new heights. And with improved quality and professionalism in the final product, your creations will leave a lasting impression.

Improved Quality and Professionalism in the Final Product

Now that you’ve learned about the expanded design possibilities that come with optimizing designs for laser cutting for glass etching, let’s dive into how it can improve the quality and professionalism of the final product.

By utilizing laser cutting techniques, you can achieve unparalleled precision and intricacy in your designs, resulting in improved aesthetics. The clean and precise cuts achieved through laser cutting ensure that each detail of your design is accurately reproduced on the glass surface, creating a polished and professional look.

This level of craftsmanship not only enhances the overall appeal of the product but also increases customer satisfaction. Customers will appreciate the attention to detail and the high-quality finish, making them more likely to be satisfied with their purchase and potentially become repeat customers.

Frequently Asked Questions

How does laser cutting for glass etching compare to traditional etching methods in terms of precision and accuracy?

When it comes to precision and accuracy, laser cutting for glass etching leaves traditional methods in the dust. The precision comparison is like night and day, with laser cutting offering unmatched detail and intricacy.

As for accuracy comparison, laser cutting ensures consistent, flawless results every time. So, if you’re looking for perfection in your glass etching projects, there’s no better choice than laser cutting.

Remember, "Precision is the key to perfection!"

Can laser cutting for glass etching be used for large-scale production?

Yes, laser cutting for glass etching can be used for large-scale production. With its large-scale capabilities and high production efficiency, laser cutting allows for faster and more precise etching on a larger scale compared to traditional methods. This means that you can produce a higher volume of glass etched products in a shorter amount of time, making it ideal for mass production and meeting the demands of a large-scale operation.

What are the main factors that contribute to the cost-effectiveness of laser cutting for glass etching?

To achieve cost effectiveness and efficiency in laser cutting for glass etching, several factors come into play.

One of the main factors is the optimization of designs, which involves creating intricate patterns that maximize material usage and minimize waste.

Another factor is the speed and accuracy of the laser cutting machine, as faster machines can complete more projects in less time.

Additionally, using high-quality materials and proper maintenance of the equipment contribute to cost effectiveness.

Are there any limitations to the intricacy and detail that can be achieved through laser cutting for glass etching?

When it comes to laser cutting for glass etching, there are some limitations to the intricacy and detail that can be achieved. This is because laser cutting has certain constraints in terms of the thickness and fragility of the glass. However, laser cutting still allows for a high level of precision and fine details in the etching process.

With the right techniques and expertise, you can achieve remarkable intricacy and detail in glass etching using laser cutting.

How does the improved quality and professionalism in the final product impact the overall impression of the design?

Improved quality and professionalism in the final product achieved through optimizing designs for laser cutting for glass etching can greatly impact the overall impression of the design. By utilizing laser cutting technology, you can achieve intricate and detailed designs with improved efficiency.

This not only enhances the visual appeal of the product but also increases customer satisfaction. The precision and accuracy of laser cutting result in a polished and high-quality finished product, leaving a lasting impression on customers.

Conclusion

In conclusion, optimizing designs for laser cutting in glass etching offers a multitude of benefits.

With enhanced precision and accuracy, greater efficiency, and cost-effectiveness, the process becomes more efficient and streamlined.

The ability to create intricate and detailed patterns opens up endless design possibilities, resulting in improved quality and professionalism in the final product.

So why settle for less when you can elevate your glass etching projects to the next level?