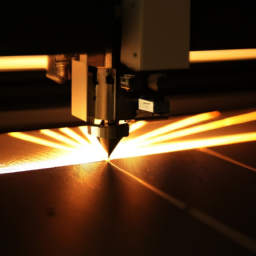

‘Measure twice, cut once.’ This timeless adage has guided woodworkers for centuries, emphasizing the importance of precision and careful planning in their craft. But what if there was a way to take this mantra to new heights? Enter laser cutting, a revolutionary technique that is transforming the world of woodworking.

By optimizing designs for laser cutting, you can unlock a plethora of benefits that will elevate your projects to new levels of precision, intricacy, and efficiency.

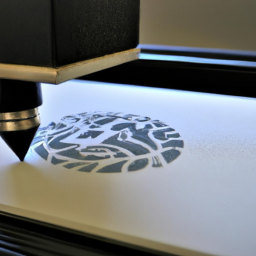

Gone are the days of painstakingly hand-cutting intricate patterns or wasting endless hours on laborious manual processes. Laser cutting offers enhanced precision and intricacy, allowing you to create intricate designs with ease. With laser cutting, you can effortlessly achieve even the most complex patterns, adding a touch of sophistication and uniqueness to your woodworking projects.

Furthermore, laser cutting saves you time and effort, streamlining the production process and increasing your productivity. By eliminating the need for manual cutting, you can focus on other aspects of your craft, such as design and finishing. In addition, optimizing designs for laser cutting offers versatility in design options, giving you the freedom to experiment with different shapes, sizes, and patterns.

Not only does laser cutting enhance the quality of your woodworking, but it also reduces material waste. Traditional cutting methods often result in significant material loss due to imprecise cuts or the need for large margins. Laser cutting minimizes waste by precisely cutting each piece, maximizing material usage and reducing your environmental impact.

In conclusion, optimizing designs for laser cutting opens a world of possibilities in woodworking. From enhanced precision and intricacy to time and effort savings, the benefits are undeniable. So, embrace the power of laser cutting and take your woodworking to new heights of excellence.

Key Takeaways

- Enhanced precision and intricacy in designs

- Saves time and effort in the production process

- Reduces material waste

- Allows for easy modification and customization of designs

Enhanced Precision and Intricacy

When you optimize designs for laser cutting, you can achieve a level of precision and intricacy that is unparalleled in traditional woodworking methods. The laser allows for increased customization, allowing you to create intricate patterns and designs that would be difficult or impossible to achieve by hand.

The laser cuts through the wood with extreme accuracy, resulting in clean edges and smooth surfaces. This precision also enhances the overall aesthetics of the finished product, giving it a professional and polished look.

By optimizing designs for laser cutting, you can save time and effort that would be spent on manual cutting and shaping. This allows you to focus on other aspects of your woodworking project, ultimately speeding up the production process and increasing efficiency.

Time and Effort Savings

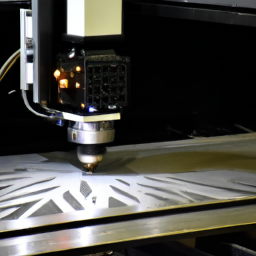

By streamlining your approach, you’ll experience incredible time and effort savings when you embrace the power of laser-cutting for your woodworking projects.

Laser cutting offers a high level of cost effectiveness, allowing you to optimize designs and minimize material waste.

Traditional woodworking methods often require manual cutting, which is time-consuming and labor-intensive.

With laser cutting, you can achieve precise and intricate cuts in a fraction of the time, reducing production time and increasing overall efficiency.

Additionally, laser cutting provides design flexibility, allowing you to easily modify and customize your designs without the need for complex tooling or setup.

This not only saves time but also enables you to quickly iterate and make adjustments as needed.

With the time and effort savings offered by laser cutting, you can explore the versatility in design options, opening up a world of possibilities for your woodworking projects.

Versatility in Design Options

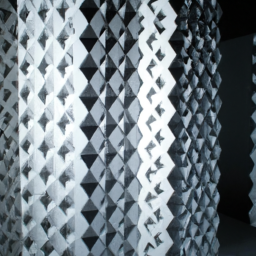

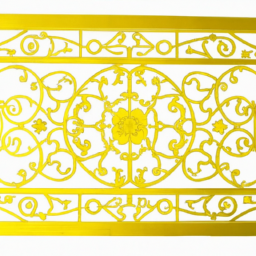

To truly unlock the potential of your woodworking projects, you’ll discover a world of endless design possibilities with the versatility offered by incorporating laser-cutting techniques.

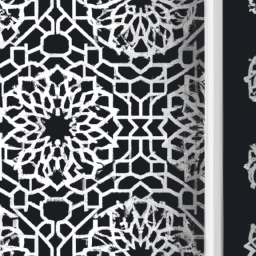

Imagine being able to effortlessly create intricate patterns and shapes in your woodwork, like a stunning lattice design on a custom cabinet door, adding a touch of elegance and uniqueness to your craftsmanship.

Laser cutting provides design flexibility that allows you to push the boundaries of traditional woodworking. With laser precision, you can achieve intricate details and complex designs that would be difficult to achieve with traditional tools.

Not only does laser cutting offer design flexibility, but it also proves to be cost-effective. By optimizing your designs for laser cutting, you can maximize material usage and minimize waste, ultimately saving you money.

And speaking of waste reduction, let’s explore how laser cutting can help minimize material waste in the next section.

Reduction in Material Waste

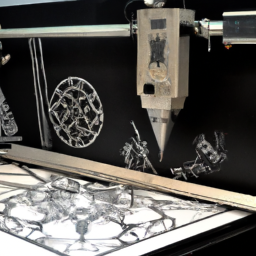

One advantage of incorporating laser-cutting techniques is the significant reduction in wasted materials, leading to cost savings and environmental sustainability. For example, a furniture manufacturer was able to minimize material waste by using laser cutting to precisely cut intricate patterns in their wooden tabletops, resulting in a 20% reduction in overall material usage.

This reduction in wasted materials not only minimizes the environmental impact but also improves cost effectiveness for woodworking projects. Laser cutting offers the following benefits to optimize designs for woodworking:

-

Precision: Laser cutting allows for precise and accurate cuts, minimizing waste by cutting only what’s necessary.

-

Efficiency: The laser cutting process is efficient, reducing the time and effort required to produce intricate designs.

-

Versatility: Laser cutting can be used on various types of wood, expanding the design possibilities for creating complex and intricate patterns.

With the reduction in material waste, laser cutting provides a cost-effective solution while still allowing for the ability to create complex and intricate patterns.

Ability to Create Complex and Intricate Patterns

Craftsmen can now effortlessly bring intricate and complex patterns to life with the remarkable ability of laser cutting. Laser cutting offers design customization like never before, allowing woodworkers to create detailed and elaborate patterns that were once extremely difficult to achieve.

With laser cutting technology, craftsmen can easily cut out intricate shapes and delicate details with precision and accuracy. This level of design customization opens up endless possibilities for creating unique and personalized woodworking projects.

Moreover, laser cutting is also cost-effective, as it allows for efficient use of materials and reduces wastage. By optimizing designs for laser cutting, woodworkers can maximize the usage of their materials, resulting in cost savings.

With the ability to create intricate patterns and the cost effectiveness of laser cutting, craftsmen can now achieve both artistic excellence and profitability in their woodworking projects. This increased efficiency and productivity contributes to the overall success of their craftsmanship.

Increased Efficiency and Productivity

Boost your productivity and efficiency with the incredible capabilities of laser cutting technology. When it comes to woodworking, optimizing designs for laser cutting can greatly improve your cost effectiveness and enhance customization opportunities.

With laser cutting, you can achieve precise and clean cuts, reducing the need for manual labor and minimizing material waste. This not only saves you time but also reduces production costs. Moreover, laser cutting allows for intricate and complex designs to be easily replicated, ensuring consistent and high-quality results every time.

By utilizing laser cutting technology, you can streamline your woodworking process, increase your output, and meet tight deadlines with ease. Say goodbye to tedious and time-consuming manual cutting, and say hello to a more efficient and productive woodworking experience.

Frequently Asked Questions

What types of materials can be used with laser cutting for woodworking?

Laser cutting for woodworking offers numerous advantages. One interesting statistic is that laser cutting can achieve precision as high as 0.1mm, ensuring intricate and detailed designs.

When it comes to materials, laser cutting can work with a wide range of options. Common applications include cutting and engraving wood, plywood, MDF, acrylic, and even leather. The versatility of laser cutting makes it an ideal choice for woodworking projects of various scales and complexities.

Are there any limitations to the size or thickness of materials that can be used with laser cutting?

Size limitations and thickness limitations are important factors to consider when using laser cutting for woodworking. The size of the material you can use depends on the size of the laser cutting machine. Most machines have a maximum cutting area, so you need to ensure that your material fits within these dimensions.

In terms of thickness, laser cutting is most effective on materials that are relatively thin, as thicker materials may require more time and power to cut through.

How does laser cutting for woodworking compare to traditional cutting methods in terms of cost?

When it comes to comparing laser cutting for woodworking with traditional cutting methods in terms of cost, you’ll find that laser cutting offers significant advantages.

The cost of laser cutting is often lower due to its precision and efficiency, which reduces material waste. Additionally, laser cutting allows for complex designs and intricate patterns that would be difficult or time-consuming to achieve with traditional methods.

This not only enhances the overall aesthetic appeal but also increases the profitability of the woodworking industry.

Can laser cutting be used for both small-scale projects and large-scale production?

Laser cutting offers numerous advantages and applications for both small-scale projects and large-scale production. With laser cutting, you can achieve precise and intricate designs, saving time and effort compared to traditional cutting methods. It allows for greater flexibility in creating customized woodwork pieces.

Additionally, laser cutting is highly efficient, reducing material waste and increasing productivity. Whether you’re working on a small project or mass production, laser cutting is a valuable tool in woodworking.

Are there any safety considerations or precautions that need to be taken when using laser cutting for woodworking?

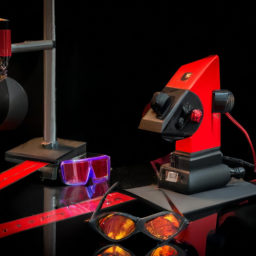

Before diving into the world of laser cutting for woodworking, it’s important to take a moment and visualize the potential hazards that may arise. Safety precautions must be a top priority, as laser cutting involves intense heat and high-powered beams.

Adequate ventilation is crucial to prevent the accumulation of harmful fumes and dust particles. To ensure a safe working environment, proper protective gear, such as goggles and gloves, should always be worn.

Conclusion

So there you have it, folks! By optimizing your designs for laser cutting in woodworking, you’ll experience a world of benefits.

From the enhanced precision and intricacy to the time and effort saved, laser cutting offers a versatile range of design options.

Not to mention, it greatly reduces material waste and allows you to create stunningly complex patterns.

With increased efficiency and productivity, laser cutting is truly a game-changer in the woodworking industry.

So why not embrace this euphoric revolution and take your woodworking skills to new heights?