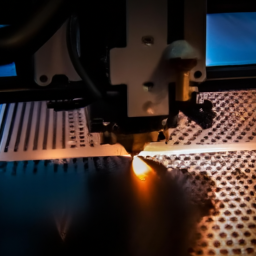

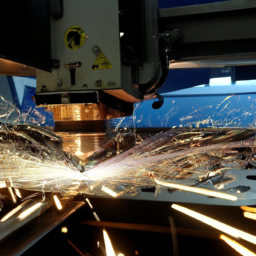

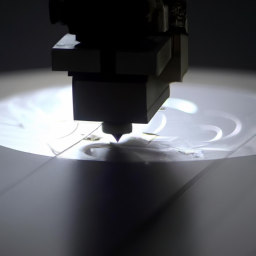

Are you looking for a cutting-edge solution to enhance your industrial processes? Look no further than subtractive laser cutting. This innovative technology offers a multitude of benefits that can revolutionize your manufacturing operations.

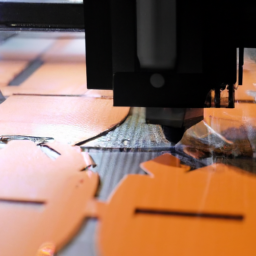

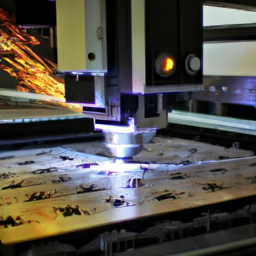

Imagine a scenario where you need to precisely cut intricate patterns on various materials, such as metal, wood, or acrylic. Subtractive laser cutting allows you to effortlessly achieve this with its versatility in material compatibility. Whether you’re working with delicate or robust materials, this method can handle them all.

Precision and accuracy are crucial in any industrial setting, and subtractive laser cutting excels in this area. With its advanced laser technology, it ensures precise cuts, intricate designs, and seamless edges, resulting in flawless end products.

Do you often work with thick materials that are challenging to cut? Subtractive laser cutting has got you covered. It effortlessly slices through thick materials, allowing for the production of sturdy and durable components.

Time and cost efficiency are key considerations for any industrial application. Subtractive laser cutting offers rapid cutting speeds, significantly reducing production time and costs. Additionally, its high precision ensures minimal rework or wastage, further optimizing efficiency.

The wide range of applications for subtractive laser cutting is astounding. From automotive and aerospace industries to architecture and electronics, this technology is versatile and adaptable to various industrial sectors.

In conclusion, subtractive laser cutting is a game-changer in the industrial world. Its versatility in material compatibility, precision, ability to cut thick materials, time and cost efficiency, minimal material waste, and wide range of applications make it an indispensable tool for enhancing manufacturing processes.

Key Takeaways

- Subtractive laser cutting offers versatility in material compatibility, allowing for precise cuts on various materials.

- It has rapid cutting speeds, reducing production time and costs.

- Subtractive laser cutting minimizes material waste and rework, optimizing efficiency.

- It allows for intricate designs and complex shapes to be easily achieved.

Versatility in Material Compatibility

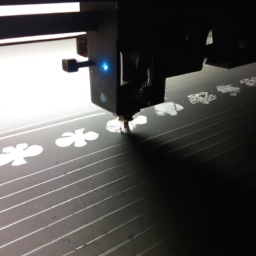

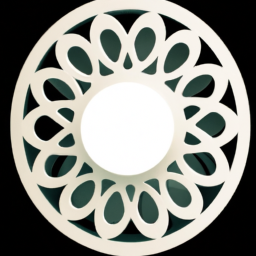

You’ll be amazed at how subtractive laser cutting can effortlessly slice through a wide range of materials, from delicate fabrics to sturdy metals, giving you the freedom to create intricate designs with ease. This technology offers exceptional compatibility with delicate materials, such as silk or lace, as it uses a focused laser beam to precisely cut without causing any damage or fraying.

This level of compatibility not only expands the possibilities for design, but also minimizes material waste and rework, ultimately increasing production efficiency. With subtractive laser cutting, you can achieve clean and precise cuts every time, ensuring your designs are flawless and ready for assembly.

Its compatibility with various materials and its impact on production efficiency make subtractive laser cutting an invaluable tool for industrial applications.

Transitioning into the next section, precision and accuracy are further enhanced by the advanced capabilities of this cutting-edge technology.

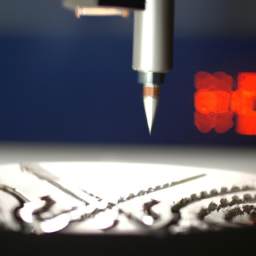

Precision and Accuracy

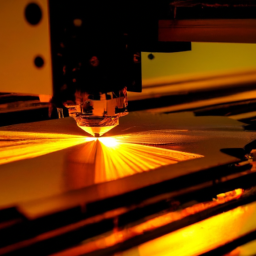

Achieving pinpoint accuracy and meticulous precision, this advanced method of fabrication ensures flawless results in a variety of practical settings. With subtractive laser cutting, you can benefit from a high level of precision and accuracy, allowing you to create intricate designs and achieve clean, sharp edges.

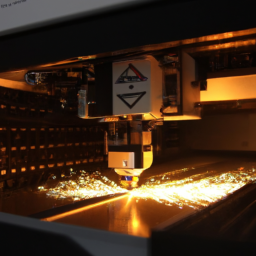

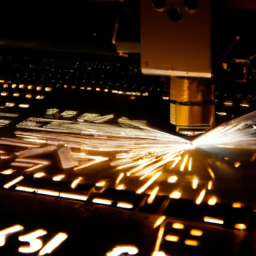

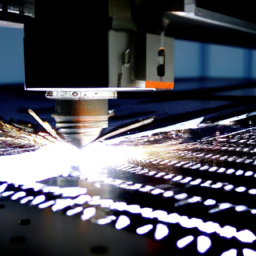

The process involves a focused laser beam that rapidly heats and vaporizes the material, resulting in precise cuts. It also improves cutting speed, making it a highly efficient option for industrial applications. Additionally, subtractive laser cutting offers the following advantages:

- Minimal heat-affected zone

- Reduced material waste

- Ability to cut complex shapes

- High repeatability

- Compatibility with a wide range of materials

This level of precision and versatility makes subtractive laser cutting an ideal choice for industries that require intricate and accurate fabrication.

Moving onto the next section about the ability to cut thick materials…

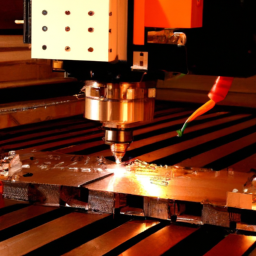

Ability to Cut Thick Materials

If you’re looking for a cutting method that can effectively handle thick materials, subtractive laser cutting is the way to go. It’s ideal for heavy-duty industrial applications where precision and accuracy are crucial. With the ability to cut through thick materials with ease, this method ensures that you can achieve the desired results efficiently and effectively.

Effective cutting through thick materials

One advantage of subtractive laser cutting is its ability to effectively cut through thick materials, making it a valuable tool for various industrial applications.

When it comes to cost-effective solutions, subtractive laser cutting offers significant benefits. Firstly, it eliminates the need for expensive tooling, reducing production costs and making it a more economical option. Secondly, it ensures high-quality results, delivering precise and accurate cuts even on thick materials. Lastly, subtractive laser cutting allows for intricate designs and complex shapes to be easily achieved, providing versatility in industrial applications.

With these advantages, subtractive laser cutting is an ideal choice for heavy-duty industrial applications where thick materials need to be cut effectively.

Ideal for heavy-duty industrial applications

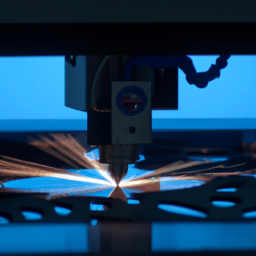

Perfect for tough industrial jobs, subtractive laser cutting is like a precision scalpel effortlessly slicing through thick materials. Its heavy-duty cutting capability makes it an ideal choice for applications that require durability and strength.

Whether it’s cutting through thick metal sheets or dense composite materials, subtractive laser cutting delivers exceptional results with minimal effort. The laser beam’s intense heat melts away the material, creating clean and precise cuts that are free from distortion or deformation. This ensures that the finished products meet the highest quality standards.

In addition to its cutting prowess, subtractive laser cutting also offers time and cost efficiency, making it a preferred method for various industrial applications. With its ability to swiftly and accurately cut through tough materials, subtractive laser cutting provides an effective solution for industrial needs.

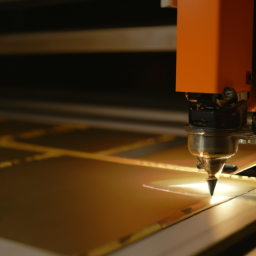

Time and Cost Efficiency

You can significantly reduce both time and cost by utilizing subtractive laser cutting for your industrial applications. With subtractive laser cutting, you can experience reduced maintenance and improved productivity.

Unlike other cutting methods, laser cutting requires minimal maintenance, saving you time and money on repairs and replacements. Additionally, laser cutting allows for precise and efficient cutting, resulting in improved productivity as you can complete more cuts in less time.

Furthermore, subtractive laser cutting minimizes material waste, ensuring that you make the most out of your materials and reducing costs associated with wasted materials.

By implementing subtractive laser cutting in your industrial applications, you can streamline your processes, optimize efficiency, and reduce both time and cost.

Minimal Material Waste

By using subtractive laser cutting, you’ll be amazed at how drastically your material waste is minimized, allowing you to make the absolute most out of your resources. Here are four reasons why this technology is so effective in reducing waste and optimizing material usage:

-

Precision cutting: Subtractive laser cutting offers unparalleled precision, enabling you to cut intricate designs with minimal material loss.

-

Nesting capabilities: The software used in laser cutting optimizes the placement of parts on the material, ensuring minimal waste by maximizing the utilization of the available space.

-

Versatile material compatibility: Laser cutting can be used on a wide range of materials, including metal, wood, plastic, and fabric, further reducing the need for multiple cutting methods.

-

Reduced environmental impact: With less material waste, subtractive laser cutting contributes to a greener manufacturing process, minimizing the environmental footprint of your operations.

With its reduced waste and enhanced design flexibility, subtractive laser cutting opens up a wide range of applications for industrial use.

Wide Range of Applications

Subtractive laser cutting has a wide range of applications, making it suitable for various industrial sectors. It is extensively used in the manufacturing, automotive, and aerospace industries.

You can rely on this technology to precisely cut and shape materials for a multitude of purposes, from creating intricate parts for machinery to fabricating components for aircraft.

Suitable for various industrial sectors

When it comes to industrial sectors, subtractive laser cutting is a versatile solution that can be applied in a variety of ways. It offers a potential for increased productivity and improved product quality.

Here are some of the sectors where subtractive laser cutting can be highly beneficial:

-

Manufacturing: Subtractive laser cutting enables precise and efficient cutting of various materials, such as metals, plastics, and composites, making it ideal for manufacturing processes.

-

Automotive: The automotive industry relies on subtractive laser cutting for tasks like cutting intricate shapes in car body panels and precision cutting of engine components.

-

Aerospace: Subtractive laser cutting is used in the aerospace industry for cutting lightweight materials like aluminum and titanium, helping to create complex structures and components.

-

Electronics: With its ability to cut intricate patterns and precise shapes, subtractive laser cutting is widely used in the electronics industry for manufacturing circuit boards and other electronic components.

These are just a few examples of how subtractive laser cutting is utilized in manufacturing, automotive, and aerospace industries.

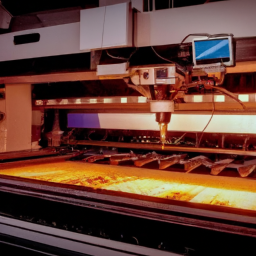

Used in manufacturing, automotive, and aerospace industries

In manufacturing, automotive, and aerospace industries, subtractive laser cutting finds its place as a versatile and indispensable solution, enhancing productivity and ensuring superior product quality.

Industrial uses of subtractive laser cutting in these sectors are extensive. In manufacturing, it’s used for precision cutting and shaping of various materials, such as metals, plastics, and composites. This allows for the creation of intricate designs and complex components.

In the automotive industry, subtractive laser cutting is utilized for fabricating body panels, interior components, and engine parts. It offers high precision and speed, resulting in efficient production processes.

Similarly, in the aerospace industry, subtractive laser cutting is utilized for manufacturing lightweight and durable components, including turbine blades and aircraft structures. It enables the creation of intricate geometries and reduces material waste.

While subtractive laser cutting offers numerous advantages, including precision and versatility, some disadvantages include high initial costs and the potential for thermal damage to materials.

Frequently Asked Questions

Can subtractive laser cutting be used on non-metallic materials?

Yes, subtractive laser cutting can indeed be used on non-metallic materials. There are numerous benefits to using this technology on such materials.

Advancements in subtractive laser cutting technology have greatly improved precision and accuracy, allowing for intricate and detailed designs. This makes it ideal for applications in industries such as textiles, plastics, wood, and more.

The versatility and efficiency of subtractive laser cutting on non-metallic materials have revolutionized manufacturing processes and opened up new possibilities for creative design and production.

What is the typical tolerance level for precision and accuracy in subtractive laser cutting?

Typical tolerance levels in subtractive laser cutting can vary depending on the specific application and material being used. However, in the automotive industry, precision and accuracy are crucial for producing high-quality parts. Laser cutting offers a level of precision that traditional cutting methods can’t match, with tolerances as low as 0.1mm.

This makes it an ideal choice for automotive manufacturers who require precise and consistent cuts for components like dashboards, door panels, and engine parts.

Is it possible to cut through materials thicker than 1 inch using subtractive laser cutting?

Yes, it’s possible to cut through materials thicker than 1 inch using subtractive laser cutting. Advancements in laser technology have led to the development of high-powered lasers that can effectively cut through thicker materials. By using these high-powered lasers, you can achieve precise and accurate cuts, even in materials that are traditionally considered difficult to cut.

This allows for greater flexibility and efficiency in industrial applications.

How does subtractive laser cutting compare to other cutting methods in terms of time and cost efficiency?

Subtractive laser cutting offers several advantages over other cutting methods in terms of time and cost efficiency. For example, let’s consider a hypothetical case where a company needs to cut intricate patterns on a metal sheet. Using traditional methods like manual cutting or waterjet cutting would be time-consuming and expensive.

However, with subtractive laser cutting, the process is faster and more cost-effective. Factors like the laser power, material thickness, and cutting speed can affect the efficiency, but overall, subtractive laser cutting proves to be a superior option.

What measures are taken to minimize material waste in subtractive laser cutting?

To minimize material waste in subtractive laser cutting, there are several techniques you can employ.

One approach is using nesting software, which optimizes the placement of parts on the material sheet to reduce waste.

Additionally, advancements in laser cutting technology have enabled the use of real-time monitoring and control systems. These systems help to ensure precise cutting, minimizing errors and reducing material waste.

By implementing these techniques and leveraging improved laser cutting technology, you can greatly increase efficiency and minimize material waste in subtractive laser cutting processes.

Conclusion

In conclusion, subtractive laser cutting offers numerous benefits for industrial applications. You can appreciate its versatility as it’s compatible with various materials, allowing for diverse project possibilities.

Its precision and accuracy ensure flawless cuts, saving you time and resources. Interestingly, studies have shown that subtractive laser cutting reduces material waste by up to 90%, making it an environmentally friendly option.

So, whether you need to cut thick materials or want a cost-effective solution, this technology has got you covered.