Like a master sculptor carving marble with a precision instrument, you can effortlessly shape and mold acrylic to create stunning works of art or functional designs that defy imagination. But to truly bring your visions to life, you need the right tools. Enter design software for laser cutting, a powerful ally in your acrylic fabrication journey.

Imagine having a digital chisel that can flawlessly cut through acrylic with utmost precision and accuracy, leaving clean edges that rival the finest craftsmanship. With this software, you can unleash your creativity and unlock a world of possibilities. Not only does it save you time and effort, but it also offers a plethora of design options, allowing you to realize even the most intricate ideas.

Cost-effective and environmentally friendly, laser cutting software minimizes waste and material loss. Whether you’re a hobbyist or a seasoned professional, this accessible and user-friendly technology will revolutionize your acrylic fabrication process, ensuring perfection in every project.

Key Takeaways

- Laser cutting software for acrylic design enhances the overall aesthetic appeal and durability of the final product.

- Laser cutting software for acrylic design offers enhanced design capabilities, allowing for customization and experimentation with colors, textures, and finishes.

- Laser cutting software for acrylic design improves accuracy and precision, resulting in faster turnaround times and cost savings.

- Laser cutting software for acrylic design optimizes material usage, minimizing waste and material loss, and streamlining the production process.

Precision and Accuracy in Cutting Acrylic

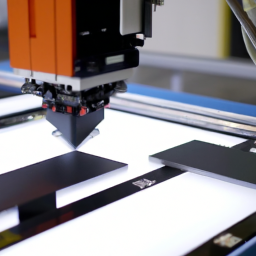

You’ll find that using design software for laser cutting acrylic allows for precise and accurate cuts, ensuring a level of sophistication in your acrylic fabrication projects. The improved productivity and enhanced product quality that comes with this technology is unparalleled.

Design software enables you to create complex patterns and intricate designs with utmost precision, eliminating the risk of human error. The laser cutter follows the exact specifications provided by the software, resulting in clean, smooth cuts every time. This level of precision not only enhances the overall aesthetic appeal of your acrylic creations but also increases their durability and functionality.

By utilizing design software for laser cutting, you can streamline your acrylic fabrication process, saving both time and effort. This efficient and time-saving process will be further explored in the subsequent section.

Efficient and Time-Saving Process

Maximize your productivity and streamline your workflow with the efficient and time-saving process offered by utilizing this advanced design software for laser cutting in acrylic fabrication. This software has revolutionized the industry by significantly improving productivity and increasing profitability.

Here are five key benefits of using this software:

-

Enhanced design capabilities: With this software, you can create intricate and complex designs with ease, allowing for greater creativity and customization.

-

Improved accuracy and precision: The software ensures precise cutting measurements, reducing material waste and minimizing errors.

-

Faster turnaround times: The automated features of the software streamline the cutting process, enabling faster production and delivery of acrylic products.

-

Cost savings: By optimizing material usage and reducing manufacturing time, this software helps to minimize costs and maximize profits.

-

Seamless integration: The software seamlessly integrates with laser cutting machines, providing a seamless workflow and eliminating compatibility issues.

By leveraging these advantages, you can enhance your acrylic fabrication business and explore a wide range of versatile design options.

Versatile Design Options

Explore a world of endless possibilities with the wide range of versatile design options available to you through this advanced software for laser cutting in acrylic fabrication. With this software, you can unleash your creativity and customize your designs to meet your exact specifications. Whether you want to create intricate patterns or unique shapes, the software allows you to easily manipulate and modify your designs. You can experiment with different colors, textures, and finishes to achieve the desired aesthetic for your acrylic fabrication projects. The software also offers a variety of tools and features that enable you to create complex designs with precision and accuracy. By utilizing these customization options, you can bring your vision to life and create stunning acrylic pieces that are truly one-of-a-kind. This level of versatility in design not only enhances the creative process but also opens up new opportunities for innovation and experimentation in acrylic fabrication. As you delve into the exciting world of design possibilities, you’ll soon discover the cost-effectiveness in production that this software offers.

Cost-Effectiveness in Production

Save money and increase efficiency by utilizing this advanced software for laser cutting in acrylic fabrication. With cost-saving measures and improved productivity, it’s a smart investment for any acrylic fabrication business. Here are three key benefits of using design software for laser cutting:

-

Optimized Material Usage: The software allows you to nest multiple designs on a single sheet of acrylic, minimizing waste and maximizing the use of every inch of material. This reduces costs associated with purchasing additional acrylic sheets.

-

Streamlined Production Process: The software automates the design-to-cut process, eliminating the need for manual measurements and calculations. This saves time and reduces the chance of human error, resulting in faster production and increased productivity.

-

Enhanced Design Capabilities: The software provides advanced design tools, allowing you to create intricate and complex designs with ease. This opens up a world of possibilities, enabling you to offer unique and customized products to your customers.

By reducing waste and material loss, this software not only saves costs but also promotes sustainability in acrylic fabrication.

Reduced Waste and Material Loss

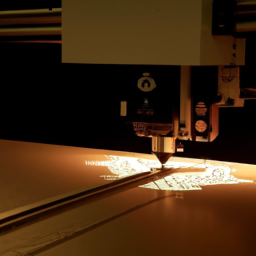

You’ll be amazed at how this advanced software for laser cutting in acrylic fabrication dramatically reduces waste and material loss, leaving you with more bang for your buck. By utilizing precise measurements and optimizing the placement of designs, this software enables sustainability practices by minimizing the amount of acrylic material needed for each project.

With traditional cutting methods, there is often a significant amount of material discarded as waste. However, with the use of design software, you can maximize the utilization of each sheet of acrylic, reducing waste and saving costs. Not only does this benefit your bottom line, but it also contributes to increased productivity, as you can complete more projects with the same amount of material.

Now, let’s explore how this software enhances accessibility and ease of use for hobbyists and professionals alike.

Accessibility and Ease of Use for Hobbyists and Professionals

With its user-friendly interface and intuitive features, this advanced software seamlessly accommodates both hobbyists and professionals, revolutionizing the accessibility and ease of acrylic fabrication. Here are three ways this software enhances the experience:

-

Affordability: The design software for laser cutting offers an affordable solution for those interested in acrylic fabrication. Unlike traditional methods that require expensive equipment and specialized skills, this software allows hobbyists and professionals to create intricate designs without breaking the bank.

-

Learning Curve: The user-friendly interface of the software significantly reduces the learning curve, making it accessible to individuals with varying levels of expertise. Whether you’re a beginner or an experienced designer, this software simplifies the design process, allowing you to easily create and modify designs for laser cutting.

-

Intuitive Features: The software provides a wide range of intuitive features that streamline the fabrication process. From precise measurements and alignment tools to efficient nesting algorithms, these features ensure optimal material usage and minimize waste. Whether you’re creating prototypes or mass-producing products, this software enhances efficiency and accuracy in acrylic fabrication.

Frequently Asked Questions

Can laser cutting software be used for materials other than acrylic?

Of course, laser cutting software can be used for materials other than acrylic. It’s like using a Lamborghini to drive to the grocery store. Sure, you can do it, but why not take advantage of its full potential? With the right software, you can cut through a wide range of alternative materials such as wood, metal, fabric, and more.

However, keep in mind that each material has its own advantages and disadvantages when it comes to laser cutting.

How long does it typically take to learn how to use design software for laser cutting?

To master design software for laser cutting, you’ll need to navigate the learning curve, which varies depending on your prior experience with similar tools. On average, it may take a few weeks to become proficient in the software’s functionalities, such as creating and editing designs, generating cutting paths, and adjusting settings.

However, mastering laser cutting software requires continuous practice and experimentation. Devoting a significant amount of time each week, around 10-20 hours, will help you become confident and efficient in utilizing its features.

Is it possible to create intricate and detailed designs with laser cutting software?

Yes, laser cutting software has the capabilities to create intricate and detailed designs. With this software, you can easily manipulate and customize your designs to achieve the desired level of complexity.

The advantages of using laser cutting software include precise control over cutting paths, the ability to work with various file formats, and the option to simulate and test designs before production. These features ensure high accuracy and efficiency in creating intricate designs for laser cutting projects.

Can laser cutting software be integrated with other manufacturing processes?

Laser cutting software can indeed be integrated with other manufacturing processes, such as additive manufacturing and CNC milling techniques.

The integration possibilities of laser cutting software with additive manufacturing processes allow for the creation of intricate and complex designs.

Additionally, exploring the compatibility of laser cutting software with CNC milling techniques enables the production of highly precise and detailed products.

This integration opens up a world of possibilities for manufacturers looking to optimize their fabrication processes.

Are there any limitations to the size and thickness of acrylic that can be cut using laser cutting software?

There are limitations to the size and thickness of acrylic that can be cut using laser cutting software. The maximum size and thickness depend on the power and capabilities of the laser cutter. Generally, laser cutting is best suited for thinner acrylic sheets, typically up to a maximum thickness of 1 inch. Thicker acrylic may require multiple passes or alternative cutting methods. However, using design software for laser cutting offers advantages such as precision, intricate designs, and quick prototyping.

Conclusion

In conclusion, utilizing design software for laser cutting in acrylic fabrication can bring forth a multitude of advantageous outcomes.

The precision and accuracy achieved through this process are truly remarkable, ensuring flawless outcomes.

Moreover, the efficiency and time-saving nature of this method allow for increased productivity and enhanced workflow.

The diverse design options available cater to a variety of needs and preferences, while the cost-effectiveness of production further adds to its appeal.

Additionally, the reduced waste and material loss contribute to a more sustainable approach.

Lastly, the accessibility and user-friendly nature of this software make it suitable for both hobbyists and professionals alike.

Embracing this technology undoubtedly elevates your acrylic fabrication endeavors to new heights.