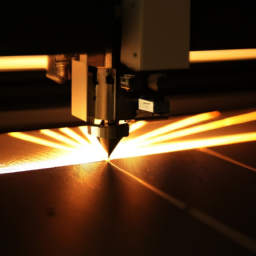

Imagine you have a vision for a masterpiece, a design that will leave others in awe. You want to bring it to life, but there’s one problem – the size of the material. Large materials can be tricky to cut with precision, but fear not! In this article, we will guide you through the best designs for laser cutting large materials, ensuring your creations are nothing short of spectacular.

Just like a sculptor needs the right tools to carve a masterpiece, you need to choose the right material for laser cutting. Whether it’s wood, acrylic, or metal, selecting the correct material is crucial for achieving clean and precise cuts.

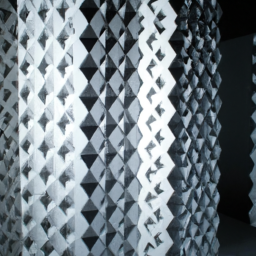

But it doesn’t stop there. Intricate patterns can elevate your design to the next level. We’ll show you how to create intricate patterns that will dazzle the eye and add depth and dimension to your large-scale projects.

Optimizing your design files is essential for a successful laser cutting experience. We’ll walk you through the process, ensuring your files are ready to be transformed into stunning works of art.

Consider the size and shape of your material – it’s the canvas upon which your design will come to life. We’ll provide tips on how to work with large materials, making the most of their size while maintaining precision and detail.

Support structures are your best friends when it comes to cutting large designs. We’ll show you how to strategically place these structures, ensuring your masterpiece remains intact throughout the cutting process.

Finally, testing and adjusting the settings for laser cutting large materials is essential for achieving optimal results. We’ll guide you through the process, allowing you to fine-tune your settings and bring your design to life with perfection.

Get ready to embark on a journey of creativity and precision as we explore the best designs for laser cutting large materials. Let’s turn your vision into a reality that will leave others amazed.

Key Takeaways

- Choosing the right material is crucial for laser cutting large objects

- Experimenting with different patterns and designs is encouraged

- Design files should be optimized and converted to vector format for accurate cuts

- Support structures are important for preventing distortion and providing stability during the cutting process

Choose the Right Material for Laser Cutting

Now, let’s talk about how you can choose the perfect material for laser cutting! When it comes to cutting large objects, it’s important to choose suitable materials that can withstand the intense heat and precision of laser cutting.

One of the best materials for this purpose is plywood, as it’s strong, versatile, and readily available. Another great option is acrylic, which is lightweight and offers a wide range of colors and finishes.

Additionally, metal sheets like steel and aluminum can be used for cutting large objects, but they require more power and specialized equipment. To ensure successful laser cutting, make sure to select materials that are within the laser’s power and speed limits.

Now, let’s move on to the next section where we’ll explore how to create intricate patterns for laser cutting.

Create Intricate Patterns for Laser Cutting

When creating intricate patterns for laser cutting, it’s important to use vector graphics software to ensure precise and accurate designs. Experimenting with different patterns and designs can help you find the perfect combination that’ll make your laser-cut project stand out.

Don’t be afraid to think outside the box and try unique patterns that’ll make your project truly unique.

Use Vector Graphics Software

To achieve the best designs for laser cutting large materials, you should utilize vector graphics software for a more precise and intricate outcome. This software allows you to create complex designs with ease and ensures that every detail is accurately represented.

With vector graphics software, you have the flexibility to explore alternative software options that may better suit your needs. Additionally, it’s important to understand the limitations of vector graphics software, such as the inability to create realistic textures or effects. However, by leveraging the software’s capabilities, you can still achieve stunning results.

So, once you’ve mastered vector graphics software, you can move on to the next step of your laser cutting journey: experiment with different patterns and designs to create unique and eye-catching pieces.

Experiment with Different Patterns and Designs

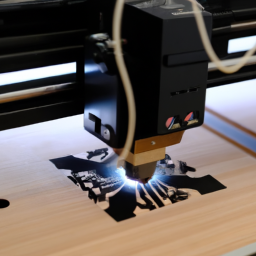

Try out various patterns and designs to unleash your creativity and bring captivating visuals to life through laser cutting. Experiment with unique shapes and explore innovative techniques to create stunning and intricate designs.

Laser cutting allows you to cut through materials with precision, giving you the freedom to experiment with different patterns and designs that would be challenging to achieve using traditional methods. Think outside the box and push the boundaries of what’s possible.

Whether you want to create intricate lace-like designs or bold geometric shapes, the possibilities are endless. By experimenting with different patterns and designs, you can find the perfect combination that’ll make your laser-cut projects truly stand out.

Once you’ve mastered the art of design, it’s time to optimize your design files for laser cutting, ensuring the best results in the next step.

Optimize Design Files for Laser Cutting

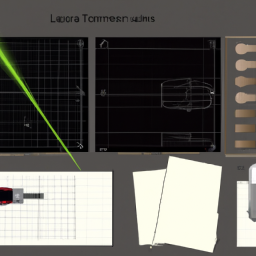

In order to optimize your design files for laser cutting, you need to convert your designs to vector format. This will ensure that the laser cutter can accurately follow the intricate patterns without any loss in quality.

Additionally, it’s important to ensure proper scaling and alignment of your design files to achieve the desired outcome. By following these key points, you can create precise and flawless laser cut designs.

Convert Designs to Vector Format

Transform your designs into a vector format and watch them come to life with the precision of a laser beam. When converting raster images to vectors, make sure to use software specifically designed for vector conversion to maintain the quality of your design.

Troubleshooting common vector conversion issues, such as jagged lines or missing details, is crucial to ensure a smooth and accurate laser cutting process. Pay attention to the resolution of your raster image and adjust it accordingly for optimal results.

Once your designs are in vector format, you can easily ensure proper scaling and alignment, allowing you to accurately cut large materials with ease. With the right tools and techniques, your laser-cut designs will be flawlessly executed every time.

Ensure Proper Scaling and Alignment

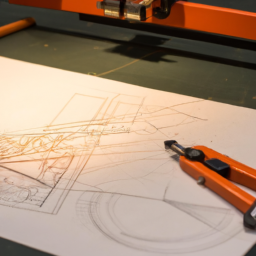

Make sure you accurately scale and align your designs to achieve precise and perfectly aligned laser cuts every time, allowing you to effortlessly create intricate and detailed projects. Here are some techniques to ensure accurate scaling and alignment for laser cutting large materials:

-

Measure twice, cut once: Take precise measurements of your material and double-check them before cutting to avoid any errors.

-

Use alignment guides: Utilize guides or registration marks to help you align your design accurately on the material.

-

Test cuts: Perform test cuts on scrap material to ensure that the scaling and alignment are correct before cutting the final piece.

-

Calibration: Regularly calibrate your laser cutter to maintain accurate scaling and alignment.

By following these techniques, you can achieve the desired precision in scaling and alignment for laser cutting large materials.

Now, let’s consider the size and shape of the material for optimal results.

Consider the Size and Shape of the Material

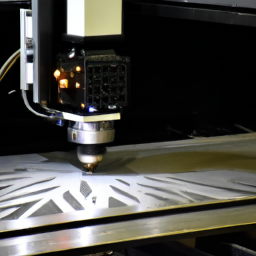

When cutting large materials with a laser, you want to think about the size and shape of the material. Consider the material thickness and select an appropriate laser cutting machine that can handle the dimensions of the material.

The size and shape of the material will determine the type of laser cutting machine you should use. If the material is too large or has an irregular shape, you may need a larger machine or one with specialized features to ensure accurate and precise cuts.

Additionally, the material thickness will affect the power and speed settings of the laser cutter. Once you have considered the size and shape of the material, you can move on to the next step: using support structures for large designs.

Use Support Structures for Large Designs

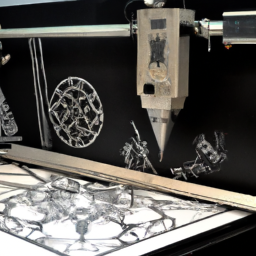

To ensure accurate and precise cuts on your large design, consider using support structures that will provide stability and prevent any potential distortion.

By incorporating 3D printing for large designs, you can create intricate support structures that can be easily attached to your material. These support structures can be designed to fit the specific shape and size of your design, ensuring maximum stability during the laser cutting process.

Additionally, incorporating multiple layers within the support structures can add further support and prevent any warping or bending of the material. This technique is especially useful for cutting large materials that are prone to distortion, such as thin sheets or delicate fabrics.

With the proper support structures in place, you can confidently proceed to the next step of testing and adjusting the settings for laser cutting large materials.

Test and Adjust Settings for Laser Cutting Large Materials

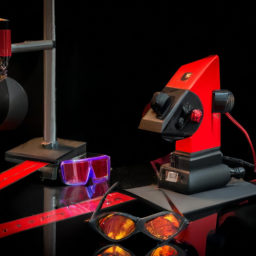

Now that you’ve learned about using support structures for laser cutting large designs, it’s time to dive into the next step: testing and adjusting settings for cutting large materials.

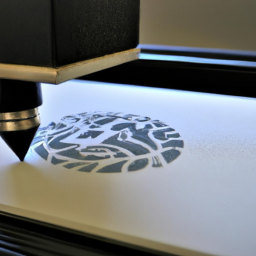

This crucial phase ensures that your laser cutter is compatible with the materials you’re working with. To start, conduct a test on a small section of the material to determine the compatibility. Based on the results, you can then fine-tune the laser power and speed settings accordingly.

Adjusting the laser power allows you to find the optimal balance between cutting through the material and avoiding excessive burning or charring. Similarly, adjusting the speed ensures that the laser moves at a pace that achieves clean and precise cuts.

By rigorously testing and adjusting these settings, you’ll achieve the best results when laser cutting large materials.

Frequently Asked Questions

What are the typical thicknesses of materials that can be cut using laser cutting?

When it comes to laser cutting, the advantages for thick materials are numerous. Laser cutting is capable of cutting a wide range of materials, including metals, plastics, and woods.

Common applications for laser cutting of large materials include fabrication of structural components, signage, and architectural elements. Laser cutting can handle materials of varying thicknesses, from thin sheets to thicker blocks, making it a versatile and efficient choice for cutting large materials.

Is there a limit to the size of the material that can be cut using laser cutting?

Is there a limit to the size of material you can cut with laser cutting?

While laser cutting can handle a wide range of thicknesses, cutting oversized materials poses potential challenges.

The advantages of laser cutting for large scale projects include precision, versatility, and the ability to create intricate designs.

However, the process may be slower and more expensive compared to other cutting methods.

It’s important to consider the size and thickness of the material when using laser cutting for large projects.

How long does it usually take to cut large materials using laser cutting?

Factors affecting the cutting time of large materials using laser cutting include the thickness and type of material, the power of the laser, and the complexity of the design. To optimize the cutting process for faster results, you can adjust the laser power and cutting speed, use efficient cutting paths, and minimize unnecessary movements.

Additionally, using optimized file formats and ensuring proper maintenance of the laser cutter can also contribute to reducing cutting time.

Can laser cutting be used on different types of materials, such as wood, metal, and acrylic?

Laser cutting can indeed be used on different types of materials, including wood, metal, and acrylic. The advantages of laser cutting on these materials include precision, clean cuts, and the ability to create intricate designs. However, there are also some disadvantages, such as the potential for heat damage and limitations on the thickness of materials that can be cut.

To optimize laser cutting for large material projects, it’s important to ensure proper ventilation, use the right power settings, and consider the design layout to minimize waste.

Are there any safety precautions that need to be taken when using laser cutting for large materials?

When using laser cutting for large materials, there are several safety measures to consider. First and foremost, proper ventilation is crucial to prevent the buildup of harmful fumes and smoke. Ensure that your workspace is well-ventilated and equipped with exhaust systems.

Additionally, wearing appropriate protective gear like safety goggles and gloves is essential. Regular maintenance of the laser cutting machine and following all manufacturer guidelines will further enhance safety during the process.

Conclusion

In conclusion, when it comes to laser cutting large materials, it’s crucial to make the right choices.

From selecting the appropriate material to creating intricate patterns, optimizing design files, and considering the size and shape of the material, attention to detail is key.

Don’t forget to use support structures for added stability. And remember, Rome wasn’t built in a day – testing and adjusting the laser cutting settings for large materials may take time.

So, keep your eyes on the prize and don’t rush the process. As they say, patience is a virtue, and it’ll lead you to success in laser cutting large materials.