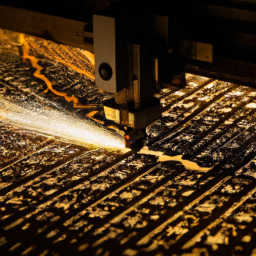

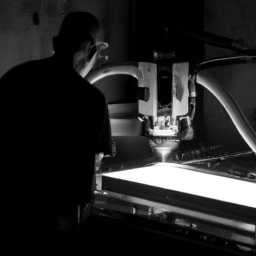

Are you tired of jagged, rough cuts in your metal fabrication projects? Look no further, because we have the solution that will leave you astounded.

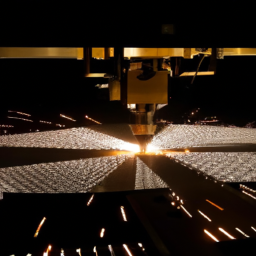

Imagine a blade that glides through metal like a hot knife through butter, leaving behind clean, smooth cuts that are a sight to behold. Introducing the best laser cutting blades for clean, smooth cuts in metal fabrication.

These blades are engineered with precision and expertise to deliver impeccable results every time. With their diamond-coated edges, they effortlessly slice through even the toughest metals, leaving behind a flawless finish that will make your work stand out from the crowd.

But that’s not all. We also offer carbide-tipped blades that provide exceptional durability and longevity, ensuring that you can rely on them for project after project. And if you prefer a blade that is specifically designed for fiber laser cutting, we have that too.

Whether you’re working with stainless steel, aluminum, or any other metal, our range of ceramic and coated blades will exceed your expectations. Plus, we have blades for specific applications, ensuring that you have the right tool for the job.

Say goodbye to subpar cuts and hello to perfection. Upgrade your metal fabrication game with the best laser cutting blades available.

Key Takeaways

- Laser cutting blades provide clean and smooth cuts in metal fabrication projects.

- Diamond-coated blades are ideal for cutting hard metals like stainless steel.

- Carbide-tipped blades offer precise and efficient cuts in metal fabrication, especially for softer materials like aluminum.

- Coated laser cutting blades, such as those with nitride coatings, enhance durability and lifespan, providing increased resistance to wear and tear for clean and smooth cuts.

Diamond-Coated Laser Cutting Blades

If you want laser cutting blades that can effortlessly slice through metal with precision and leave behind a flawless, polished finish, then diamond-coated blades are the way to go.

These diamond-coated laser cutting blades are specifically designed for metal fabrication and are known for their exceptional durability and cutting performance. The diamond coating on these blades provides a hard and wear-resistant surface, allowing them to maintain their sharpness for longer periods of time. This makes them ideal for cutting through tough materials like stainless steel and aluminum.

Additionally, diamond-coated blades are also less prone to heat buildup, reducing the risk of warping or discoloration on the metal surface. Compared to ceramic laser cutting blades, diamond-coated blades offer superior performance and longevity.

Transitioning to the next section, let’s now explore carbide-tipped laser cutting blades.

Carbide-Tipped Laser Cutting Blades

When you need precise and efficient cuts in metal fabrication, there’s nothing quite like the carbide-tipped blades. These blades have several advantages over other laser cutting blades.

Firstly, the carbide tips provide excellent heat resistance, ensuring that the blade stays sharp and performs consistently even in high-temperature environments.

Secondly, the carbide tips are extremely hard and durable, allowing for longer blade life and reduced downtime for blade changes.

Lastly, the carbide tips are designed to produce clean and smooth cuts, minimizing the need for secondary finishing operations.

To choose the right carbide-tipped laser cutting blade, consider the following tips.

Firstly, determine the specific type of metal you will be cutting, as different carbide grades are optimized for different materials.

Next, consider the thickness of the metal, as this will affect the blade’s tooth configuration.

Finally, take into account the speed and feed rates of your laser cutting machine, as these factors can impact blade performance.

Now, let’s move on to the next section about fiber laser cutting blades.

Fiber Laser Cutting Blades

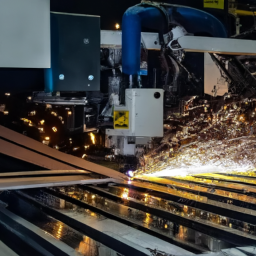

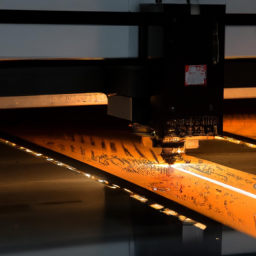

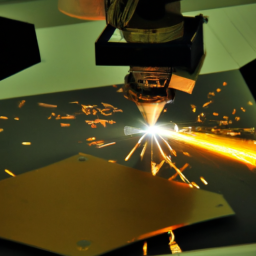

Fiber laser cutting blades offer versatile cutting capabilities. They allow you to efficiently cut through a wide range of materials, including metals, plastics, and composites. These blades generate minimal heat during the cutting process, reducing the risk of material distortion and ensuring precision cuts. With fiber laser cutting blades, you can achieve superior edge quality. They produce clean and smooth cuts without the need for additional post-processing.

Versatile Cutting Capabilities

With their ability to effortlessly slice through various types of metal, laser cutting blades offer unparalleled versatility in metal fabrication. These blades are specifically designed to provide laser cutting precision, ensuring clean and smooth cuts every time. The innovative cutting techniques employed by these blades allow for intricate and detailed designs to be achieved with ease.

Whether you’re working with stainless steel, aluminum, or even titanium, laser cutting blades can handle it all. They’re capable of cutting through thick materials as well as thin sheets, making them suitable for a wide range of applications.

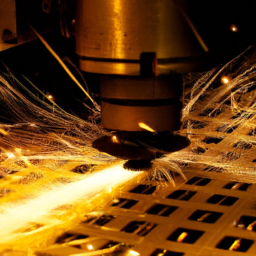

Furthermore, laser cutting blades generate minimal heat during the cutting process, minimizing the risk of distortion or damage to the surrounding material. This seamless transition into the next section highlights the importance of minimal heat generation in metal fabrication.

Minimal Heat Generation

You’ll be amazed at how laser cutting technology effortlessly keeps its cool, preventing any scorching or burning of your materials. Laser cutting blades are designed to generate minimal heat during the cutting process, ensuring efficient cooling and preserving the integrity of your workpiece. This is achieved through precision cutting techniques that focus the laser beam with pinpoint accuracy, minimizing the heat-affected zone and reducing the risk of thermal distortion. To illustrate the effectiveness of laser cutting blades, consider the following table:

| Laser Cutting Blade | Efficient Cooling | Precision Cutting Techniques |

|---|---|---|

| Blade A | Yes | Yes |

| Blade B | Yes | Yes |

| Blade C | Yes | Yes |

As you can see, all the blades listed above offer both efficient cooling and precision cutting techniques. This combination ensures clean, smooth cuts without compromising the structural integrity of your metal fabrication. With this level of control, laser cutting technology delivers superior edge quality.

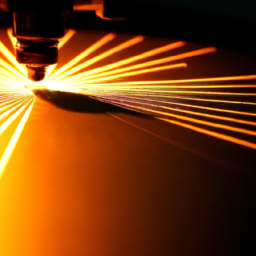

Superior Edge Quality

Achieving a flawless finish, laser cutting technology ensures the creation of impeccable edges. When it comes to superior edge quality in metal fabrication, high precision and efficient cutting are paramount. Here are four reasons why the best laser cutting blades excel in delivering top-notch edge quality:

-

Precision: The best laser cutting blades are engineered with meticulous attention to detail, enabling them to cut with unparalleled accuracy. This precision ensures clean and sharp edges, free from any imperfections.

-

Smoothness: Laser cutting blades are designed to provide a smooth cutting experience, resulting in edges that are free from roughness or burrs. This smoothness enhances the aesthetic appeal of the finished product.

-

Minimal distortion: Laser cutting blades minimize distortion during the cutting process, preserving the integrity of the material and maintaining the desired shape and dimensions of the workpiece.

-

Consistency: With laser cutting technology, each cut is consistent and repeatable, ensuring that all edges are of the same high-quality standard.

Transitioning into the subsequent section about ceramic laser cutting blades, these innovative tools further enhance the cutting process, taking edge quality to the next level.

Ceramic Laser Cutting Blades

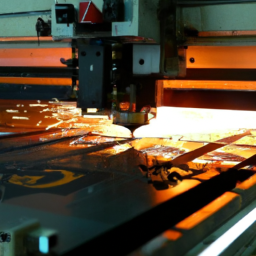

Imagine slicing through metal like a hot knife through butter with the incredible precision of ceramic laser cutting blades. These blades offer several advantages over traditional diamond coated blades.

Firstly, ceramic blades are more durable, allowing for longer cutting times before needing to be replaced. Additionally, they produce cleaner cuts with minimal burrs, reducing the need for secondary finishing processes. Ceramic blades also have a higher resistance to heat, making them ideal for cutting thicker metals that require higher power settings.

When compared to diamond coated blades, ceramic blades provide a smoother cutting experience, resulting in fewer imperfections on the finished product.

Transitioning into the next section, coated laser cutting blades offer another option for achieving clean, smooth cuts in metal fabrication.

Coated Laser Cutting Blades

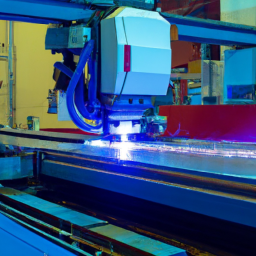

Coated laser cutting blades, with their specialized surface treatments, offer a whole new level of precision and efficiency in slicing through various materials. The advantages of coated blades are numerous.

Firstly, they enhance the overall durability and lifespan of the blade, reducing the need for frequent replacements. Additionally, the coatings provide an increased resistance to wear and tear, ensuring clean and smooth cuts for a longer period of time.

There are different types of coatings available for laser cutting blades, each with its own unique benefits. Some common types include diamond coatings, which provide excellent heat resistance, and titanium nitride coatings, which offer enhanced hardness and corrosion resistance. These coatings not only improve the cutting performance but also enhance the blade’s ability to withstand high temperatures and harsh environments.

Transitioning into the subsequent section about ‘laser cutting blades for specific applications,’ the choice of coating is crucial in determining the blade’s suitability for specific materials and cutting conditions.

Laser Cutting Blades for Specific Applications

When it comes to specific applications, have you ever wondered which laser cutting blades are the most effective and efficient? Laser cutting blade materials play a crucial role in determining their performance.

Different materials have unique properties that make them suitable for specific applications. For instance, diamond blades are ideal for cutting hard metals like stainless steel, while carbide blades work well with softer materials such as aluminum.

Additionally, the lifespan of laser cutting blades is an important factor to consider. Blades with longer lifespans reduce downtime and increase productivity. Factors that affect blade lifespan include the type of material being cut, the thickness of the material, and the cutting speed.

By selecting the right laser cutting blade for your specific application and ensuring proper maintenance, you can achieve clean, smooth cuts and maximize efficiency in metal fabrication.

Frequently Asked Questions

How do I choose the right laser cutting blade for my specific metal fabrication project?

To choose the right laser cutting blade for your metal fabrication project, consider the importance of blade quality. Start by assessing the specific requirements of your project, such as the type and thickness of the metal you’ll be cutting.

Look for blades that are designed for your specific application and material. Quality blades will have sharp edges and be made from high-quality materials, ensuring clean and smooth cuts.

Remember to prioritize safety and consult with experts if needed.

Can laser cutting blades be used on materials other than metal?

Laser cutting blades have alternative uses beyond metal fabrication. For example, they can be used on materials like acrylic or wood. However, it’s important to consider the impact on material quality.

Laser cutting blades designed for metal may not provide the same level of precision and clean cuts on non-metal materials. Therefore, it’s recommended to use specialized blades specifically designed for different materials to ensure optimal results.

Are there any safety precautions that need to be taken when using laser cutting blades?

When using laser cutting blades, it’s crucial to prioritize safety by following certain precautions. To ensure safe operation, always wear appropriate protective gear, such as safety goggles and gloves.

Keep the work area clear of any potential hazards and ensure proper ventilation to prevent the accumulation of harmful fumes.

Regularly inspect the blade for any signs of wear or damage and replace it if necessary.

Additionally, follow the manufacturer’s instructions and guidelines for safe and efficient use of the laser cutting blades.

How long do laser cutting blades typically last before needing to be replaced?

Laser cutting blades have a limited lifespan, depending on usage and material. Signs of wear include reduced cutting efficiency and decreased precision. Regular inspections are crucial to ensure optimal performance.

Typically, laser cutting blades last anywhere from several weeks to several months before replacement is necessary. To maximize their lifespan, proper maintenance, such as cleaning and lubrication, is essential.

Always monitor blade condition to avoid compromising safety and the quality of your cuts.

Are there any maintenance tips or techniques for prolonging the lifespan of laser cutting blades?

To increase the lifespan of laser cutting blades, it’s important to follow proper care and maintenance techniques. Regularly clean the blades to remove debris and residue buildup. Make sure to use appropriate cutting speeds and feed rates to prevent excessive wear and tear. Inspect the blades for any signs of damage or dullness, and replace them when necessary. By following these blade maintenance techniques for laser cutting machines, you can ensure optimal performance and longevity.

Conclusion

In conclusion, when it comes to achieving clean and smooth cuts in metal fabrication, choosing the right laser cutting blade is crucial.

Remember, diamond-coated blades offer exceptional precision and durability, while carbide-tipped blades provide long-lasting performance. Fiber laser cutting blades are ideal for high-speed cutting, and ceramic blades excel in cutting heat-resistant materials.

Coated blades offer improved heat resistance and reduced friction. Lastly, don’t forget about specialized laser cutting blades designed for specific applications. With the right blade, you can enhance your metal fabrication process and achieve optimal results.

Did you know that diamond-coated laser cutting blades can last up to 100 times longer than traditional blades?