Are you in the metal fabrication industry and seeking the most efficient and precise way to cut aluminum? Look no further than laser cutting machines. These cutting-edge devices utilize the power of lasers to effortlessly slice through aluminum with unparalleled accuracy. Whether you’re a small-scale workshop or a large manufacturing plant, investing in the best laser cutting machine is crucial for optimizing your metal fabrication process.

In this article, we will explore the top laser cutting machines specifically designed for cutting aluminum. From fiber laser cutting machines that offer high cutting speeds and exceptional precision to CO2 laser cutting machines that are ideal for thicker aluminum sheets, we’ve got you covered.

YAG laser cutting machines, known for their reliability and cost-effectiveness, will also be discussed. Additionally, we will delve into hybrid laser cutting machines that combine the best features of different laser technologies.

Furthermore, we will explore CNC laser cutting machines that provide automated and programmable cutting processes, as well as portable laser cutting machines for on-the-go metal fabrication needs. So, join us as we delve into the world of laser cutting machines and find the perfect solution to enhance your aluminum cutting capabilities.

Key Takeaways

- Laser cutting machines are efficient and precise tools for cutting aluminum in the metal fabrication industry.

- Different types of laser cutting machines, such as fiber, CO2, YAG, hybrid, CNC, and portable, offer various features and benefits for cutting aluminum.

- Laser cutting machines provide high-speed cutting, superior precision, and the ability to handle a wide range of materials and thicknesses, making them versatile and cost-effective.

- Factors to consider when choosing a laser cutting machine for cutting aluminum include power, machine bed size, and compatibility with different thicknesses of aluminum.

Fiber laser cutting machines

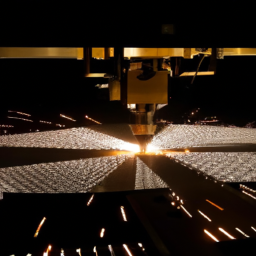

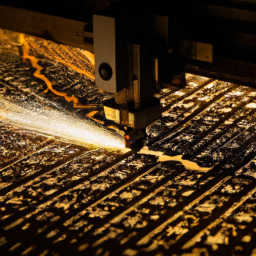

You’ll be amazed at how effortlessly fiber laser cutting machines slice through aluminum, leaving behind precise and clean edges that shimmer in the light. These cutting-edge machines offer several advantages for cutting aluminum in metal fabrication.

Firstly, fiber laser cutting machines provide high cutting speeds, allowing for increased productivity and reduced production time. Additionally, they have a smaller heat-affected zone, minimizing the risk of warping or distortion in the aluminum sheet. With their superior beam quality, fiber laser cutting machines can achieve intricate and complex cuts with extreme precision.

However, it’s important to note that fiber laser cutting machines have some limitations. They are generally not suitable for cutting thick aluminum sheets, as their power density decreases with increasing material thickness.

As we move on to discussing CO2 laser cutting machines, it’s important to understand the unique strengths of each technology.

CO2 laser cutting machines

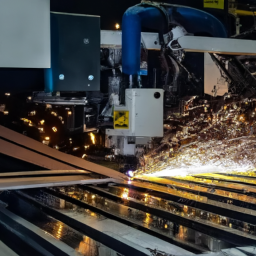

CO2 laser cutting machines are a versatile option for cutting various materials, including aluminum, in metal fabrication. They are capable of handling thicker aluminum sheets, providing you with the flexibility to work with a range of thicknesses.

Moreover, these machines offer an affordable initial investment, making them a cost-effective choice for businesses looking to integrate laser cutting technology into their operations.

Versatile for various materials including aluminum

With its ability to handle various materials, including aluminum, these laser cutting machines are truly versatile in metal fabrication.

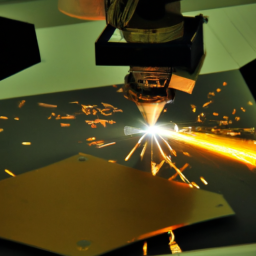

Aluminum cutting techniques:

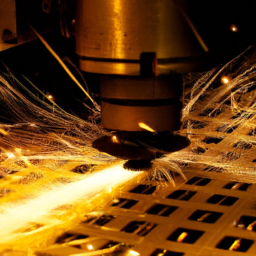

- The laser beam melts the aluminum, while a high-pressure gas blows away the molten metal, resulting in a precise cut.

- The heat-affected zone is minimal, reducing the risk of distortion or warping.

Benefits of aluminum laser cutting:

- High-speed cutting: These machines can cut aluminum at impressive speeds, improving productivity.

- Superior precision: Laser cutting provides intricate and accurate cuts, allowing for complex designs and tight tolerances.

These machines can also handle thicker aluminum sheets, making them suitable for a wide range of applications in metal fabrication.

Can handle thicker aluminum sheets

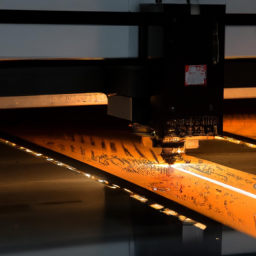

Capable of handling thicker sheets of aluminum, these machines exhibit remarkable versatility in the realm of metalworking. These machines are designed to deliver high cutting speeds, ensuring that your aluminum sheets are cut quickly and accurately. Moreover, they are equipped with advanced technologies that optimize the cutting process, resulting in precise and clean cuts. This not only saves time but also reduces material wastage, making them cost-effective in the long run.

With their ability to handle thicker aluminum sheets, these machines offer metal fabricators the flexibility to work with a variety of materials and thicknesses. Transitioning to the subsequent section about ‘affordable initial investment’, these machines prove to be a wise choice for metal fabricators looking for a reliable and efficient solution.

Affordable initial investment

If you’re in the market for a laser cutter, you’ll be pleased to know that the initial investment for these machines can be surprisingly affordable, with some models starting at just a fraction of the cost of traditional cutting equipment.

Investing in a laser cutter can provide cost-effective options for cutting aluminum in metal fabrication. When considering affordability, it’s important to also consider the durability and reliability of the machine. Laser cutters are built to withstand heavy use and are designed with high-quality components to ensure long-lasting performance. This means you can rely on your laser cutter to consistently deliver precise cuts on thicker aluminum sheets without compromising on quality.

So, not only are laser cutters a cost-effective option, they also provide the durability and reliability needed for metal fabrication.

Transitioning into the subsequent section about ‘yag laser cutting machines’, it’s important to explore their specific features and advantages.

YAG laser cutting machines

When it comes to cutting aluminum in metal fabrication, you’ll find that YAG laser cutting machines are your best bet. These portable YAG laser machines are specifically designed for high precision cutting of aluminum sheets.

The YAG, or yttrium aluminum garnet, laser technology utilized in these machines allows for a focused beam of light that can cut through aluminum with incredible accuracy and speed. The high precision YAG lasers ensure clean and precise cuts, minimizing the need for additional finishing processes.

With their compact size and portability, these machines can be easily moved around the workshop, making them ideal for small-scale metal fabrication operations. However, if you’re looking for a machine that offers even more versatility, you might want to consider hybrid laser cutting machines, which combine the benefits of YAG lasers with other cutting technologies.

Hybrid laser cutting machines

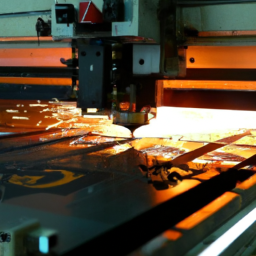

Hybrid laser cutting machines combine fiber and CO2 laser technologies, making them highly versatile for cutting different materials and thicknesses.

With their ability to switch between laser sources, these machines offer a wide range of cutting options.

They provide high cutting speed and precision, ensuring accurate and efficient results in metal fabrication processes.

Combine fiber and CO2 laser technologies

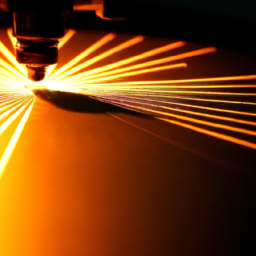

Combining fiber and CO2 laser technologies offers a significant advantage in terms of cutting speed. Some machines are capable of cutting aluminum at speeds of up to 300 inches per minute. This is due to the unique properties of each laser type. Fiber lasers are known for their high intensity and concentrated energy, allowing for efficient and precise cutting. They’re also more energy-efficient and require less maintenance compared to CO2 lasers.

On the other hand, CO2 lasers have a longer wavelength, making them better suited for cutting thicker materials. By combining the two technologies, manufacturers can take advantage of the speed and efficiency of fiber lasers while still benefiting from the cutting capabilities of CO2 lasers.

This makes the hybrid machines versatile for different materials and thicknesses, ensuring optimal performance in metal fabrication processes.

Versatile for different materials and thicknesses

You’ll be amazed at the versatility these machines offer when it comes to working with different materials and thicknesses. With advancements in laser technology, these laser cutting machines can handle a wide range of materials, such as aluminum, stainless steel, and even non-metallic materials like wood and acrylic. Different cutting techniques, such as fusion cutting and flame cutting, can be employed to achieve precise and clean cuts on various thicknesses of material.

To give you a better understanding of the capabilities of these machines, here’s a table showcasing the maximum cutting thickness for different materials:

| Material | Maximum Cutting Thickness |

|---|---|

| Aluminum | 20mm |

| Stainless Steel | 12mm |

| Wood | 30mm |

| Acrylic | 20mm |

The versatility of these machines allows for a wide range of applications in metal fabrication. Now, let’s move on to the next section about high cutting speed and precision.

High cutting speed and precision

With their exceptional speed and precision, these machines can effortlessly slice through materials like butter, making them ideal for industries that require intricate and accurate cuts, such as automotive manufacturing. When it comes to cutting aluminum in metal fabrication, laser cutting machines offer several advantages.

Firstly, laser cutting provides a clean and precise cut, minimizing the need for additional processing or finishing. Secondly, it allows for a high cutting speed, increasing productivity and reducing production time. Additionally, laser cutting machines offer excellent control over the cutting process, allowing for intricate and complex designs.

When choosing a laser cutting machine for cutting aluminum, some top considerations include the power of the laser, the size of the machine bed, and the compatibility with different thicknesses of aluminum. These factors will ensure that you can achieve the desired results efficiently and effectively.

Transitioning into the subsequent section about CNC laser cutting machines, these advanced machines take the precision and speed of laser cutting to another level.

CNC laser cutting machines

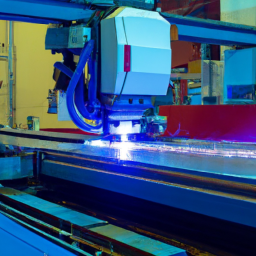

When it comes to aluminum cutting in metal fabrication, CNC laser cutting machines are the way to go! These machines offer numerous advantages and benefits, making them a popular choice in the industry.

With CNC laser cutting machines, you can achieve high cutting speed and precision, ensuring accurate and clean cuts on aluminum sheets. The CNC technology allows for automated and computer-controlled operations, eliminating the need for manual adjustments and reducing human error. This results in improved productivity and efficiency in metal fabrication processes.

Additionally, CNC laser cutting machines are known for their versatility, as they can handle a wide range of materials and thicknesses. They are also capable of intricate and complex cuts, making them ideal for various applications in metal fabrication.

Transitioning into the subsequent section about portable laser cutting machines, it’s important to consider the advantages they offer in terms of flexibility and convenience.

Portable laser cutting machines

Imagine the freedom and convenience of having a portable laser cutter at your fingertips, allowing you to create intricate designs and cuts anywhere you go. Portable laser cutting machines have revolutionized the world of metal fabrication by providing affordable options for on-the-go fabrication needs.

These compact machines offer a range of benefits, including:

-

Versatility: Portable laser cutting machines are designed to handle various materials, including aluminum, with precision and ease.

-

Precision: These machines utilize advanced laser technology to ensure precise and accurate cuts, even on complex designs.

-

Portability: With their compact size and lightweight construction, portable laser cutting machines can be easily transported and used in different locations.

-

Convenience: Gone are the days of relying on fixed workshop setups. Portable laser cutting machines enable you to work on projects wherever and whenever you want.

Investing in a portable laser cutting machine is a practical choice for metal fabricators who value flexibility and affordability without compromising on quality and precision.

Frequently Asked Questions

What are the main differences between fiber laser cutting machines and CO2 laser cutting machines in terms of cutting aluminum?

When comparing fiber laser cutting machines to CO2 laser cutting machines for cutting aluminum, the advantages of fiber lasers become apparent.

Fiber lasers, unlike CO2 lasers, use a solid-state laser source, allowing for higher cutting speeds and greater precision. The fiber lasers’ wavelength is better absorbed by aluminum, resulting in cleaner cuts and less heat-affected zones.

Additionally, fiber lasers have a longer lifespan and require less maintenance, making them a preferred choice for cutting aluminum in metal fabrication.

Can YAG laser cutting machines effectively cut thick aluminum sheets in metal fabrication?

Yes, YAG laser cutting machines can effectively cut thick aluminum sheets in metal fabrication. However, fiber laser cutting machines offer several advantages for cutting aluminum.

Fiber lasers have higher cutting speeds, improved energy efficiency, and better beam quality, resulting in cleaner and more precise cuts. Additionally, fiber lasers are more cost-effective in the long run due to their lower maintenance requirements and longer lifespan.

Therefore, when cutting thick aluminum sheets, fiber laser cutting machines are often preferred over YAG lasers.

Are hybrid laser cutting machines suitable for cutting both aluminum and other metals?

Hybrid laser cutting machines are indeed suitable for cutting both aluminum and other metals. When compared to traditional laser cutting machines, hybrids offer several advantages.

Firstly, hybrids utilize a combination of laser and other cutting technologies, allowing for greater versatility and precision.

Secondly, hybrids can handle a wider range of materials and thicknesses, making them ideal for metal fabrication.

Lastly, hybrids offer faster cutting speeds and reduced operational costs, making them a preferred choice for aluminum cutting.

How do CNC laser cutting machines differ from other types of laser cutting machines when it comes to aluminum cutting?

CNC laser cutting machines offer distinct advantages when it comes to cutting aluminum. They excel in delivering clean and accurate cuts, thanks to their precision and versatility. Their ability to handle intricate designs and complex geometries sets them apart from other types of laser cutting machines. Additionally, the use of CNC technology allows for efficient and automated operations, reducing human error and increasing productivity. When it comes to aluminum cutting, CNC laser cutting machines are the go-to choice for reliable and high-quality results.

Can portable laser cutting machines achieve the same level of precision and accuracy as larger, stationary machines when cutting aluminum?

Portable laser cutting machines can achieve the same level of precision and accuracy as larger, stationary machines when cutting aluminum. Despite their smaller size, portable machines offer several advantages.

They are lightweight and easy to transport, making them suitable for on-site projects. Portable machines also have advanced features such as auto-focus and real-time monitoring, ensuring precise cuts. Additionally, they are equipped with high-quality optics and advanced software, allowing for accurate and intricate aluminum cutting.

Conclusion

In conclusion, when it comes to cutting aluminum in metal fabrication, the best laser cutting machines are the fiber, CO2, YAG, hybrid, and CNC laser cutting machines.

These machines offer precise and efficient cutting, allowing for intricate designs and smooth edges. They’re like the skilled surgeons of the metal fabrication world, delicately and precisely shaping the aluminum with their laser beams.

Investing in one of these machines will undoubtedly elevate your metal fabrication projects to new heights of precision and quality.