Are you tired of spending hours cutting acrylic sheets by hand? Looking for a more efficient and precise solution? Look no further than the best Nd:YAG laser cutter for cutting acrylic sheets.

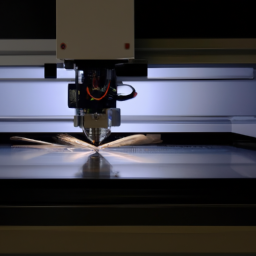

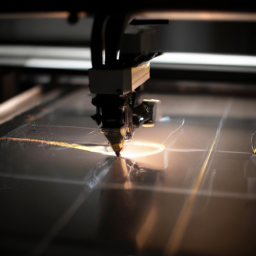

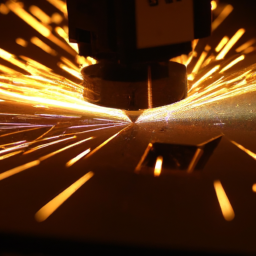

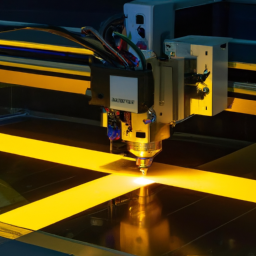

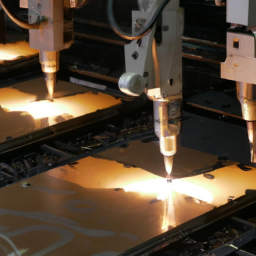

This cutting-edge technology harnesses the power of a neodymium-doped yttrium aluminum garnet (Nd:YAG) laser to deliver unparalleled precision and speed. With its focused laser beam, you can achieve clean, smooth cuts on acrylic sheets of any thickness. Say goodbye to jagged edges and time-consuming manual labor.

Whether you’re a hobbyist or a professional, this laser cutter is designed to meet your needs. With user-friendly features and software, you’ll be able to easily control the cutting process and achieve the desired results. Safety features and maintenance requirements ensure a hassle-free experience.

Plus, with its exceptional return on investment, this Nd:YAG laser cutter is a wise investment for any acrylic cutting project. Upgrade your cutting game and experience the future of acrylic sheet cutting with the best Nd:YAG laser cutter.

Key Takeaways

- Nd:YAG laser cutter is the most efficient and precise solution for cutting acrylic sheets.

- It operates at high power levels for faster cutting speeds and increased productivity.

- Minimal heat transfer to the surrounding area reduces material distortion or warping.

- User-friendly features and software, as well as regular maintenance, are important for safety and optimal performance.

Understand the Benefits of Nd:YAG Laser Technology

You’ll quickly realize the immense advantages of Nd:YAG laser technology for cutting acrylic sheets. The benefits of Nd:YAG laser technology are numerous and make it an ideal choice for acrylic sheet cutting.

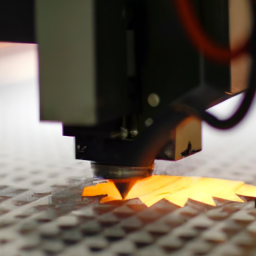

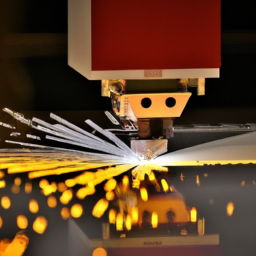

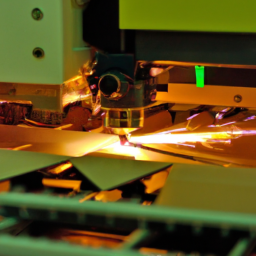

Firstly, Nd:YAG lasers have a wavelength of 1064nm, which is highly absorbed by acrylic material, resulting in precise and clean cuts. Additionally, Nd:YAG lasers can operate at high power levels, allowing for faster cutting speeds and increased productivity. The laser’s high energy density ensures minimal heat transfer to the surrounding area, reducing the risk of material distortion or warping.

Furthermore, Nd:YAG lasers are known for their ability to cut through thick acrylic sheets effortlessly. Consider the power and wattage options to further optimize your cutting process.

Transitioning into the next section, it’s essential to evaluate these factors carefully for the best results.

Consider the Power and Wattage Options

When considering the power and wattage options for your nd:YAG laser cutter, you need to determine the thickness of the acrylic sheets you’ll be cutting.

This is important because different power levels are required for different thicknesses. Once you’ve determined the thickness, you can choose the appropriate power level for your cutting needs.

This will ensure that you achieve clean and precise cuts every time.

Determine the thickness of acrylic sheets you will be cutting

To accurately cut acrylic sheets with precision, it’s essential to consider the thickness of the sheets. The maximum thickness of acrylic sheets that can be cut using an ND:YAG laser cutter depends on the power and wattage of the machine. It’s important to determine the maximum thickness that your laser cutter can handle, as attempting to cut thicker sheets may result in incomplete cuts or damage to the machine. Additionally, the type of acrylic material being used can also affect the cutting capabilities. Some acrylic materials may require higher power levels to achieve clean cuts, while others may be more easily cut with lower power levels. Determining the appropriate power level for your cutting needs will be discussed in the next section.

| [//]: # (Table) | Thickness (mm) | Recommended Power Level |

|---|---|---|

| Up to 3mm | Low | |

| 3mm – 6mm | Medium | |

| 6mm and above | High |

To ensure successful acrylic sheet cutting, it’s crucial to choose the appropriate power level for your cutting needs.

Choose the appropriate power level for your cutting needs

Finding the right power level is crucial for achieving precise cuts on acrylic sheets. To choose the appropriate power level for your cutting needs, consider the following:

-

Choosing the appropriate focal length for your cutting needs: The focal length determines the spot size and depth of focus, impacting the quality and precision of the cuts.

-

Understanding the different types of lenses for Nd:YAG laser cutting: There are three common types – plano-convex, meniscus, and aspheric lenses. Each lens type has its own advantages and limitations, affecting the beam quality and cutting performance.

-

Adjusting the power level based on the sheet thickness: Thicker sheets require higher power levels to ensure complete and efficient cutting, while thinner sheets may be successfully cut at lower power levels.

-

Considering the material characteristics: Different acrylic sheets may have varying melting points and thermal conductivity, which can influence the optimal power level for cutting.

By carefully selecting the power level, focal length, and lens type, you can ensure the best results for cutting acrylic sheets. Now, let’s move on to evaluating the cutting bed size and capacity.

Evaluate the Cutting Bed Size and Capacity

When evaluating the cutting bed size and capacity of a laser cutter for cutting acrylic sheets, you need to determine the size of acrylic sheets you’ll be working with. Make sure the laser cutter can accommodate your desired sheet size. Consider the maximum dimensions of the sheets you’ll be cutting. Ensure that the cutting bed of the laser cutter is large enough to fit them. This will ensure you can efficiently and accurately cut your acrylic sheets without any limitations or restrictions.

Determine the size of acrylic sheets you will be working with

Decide the dimensions of the acrylic sheets you’ll be handling to ensure the best fit for your nd:yag laser cutter.

To maximize efficiency and minimize waste, it’s crucial to determine the size of the acrylic sheets you’ll be working with. Consider the following factors:

-

Thickness: Determine the thickness of the acrylic sheets you’ll be cutting. This will help you choose a laser cutter with the appropriate power and settings.

-

Length and Width: Measure the maximum length and width of the acrylic sheets you plan to work with. This will ensure that the laser cutter’s cutting bed can accommodate your desired sheet size.

-

Tolerance: Consider any necessary tolerances for your projects. Some laser cutters may have limitations on the precision they can achieve.

-

Quantity: Determine the quantity of acrylic sheets you’ll be cutting at once. This will help you select a laser cutter with the necessary capacity.

By considering these factors, you can ensure that the laser cutter can accommodate your desired sheet size and meet your specific needs without compromising efficiency or wasting materials.

Ensure the laser cutter can accommodate your desired sheet size

To ensure a seamless fit, make sure the laser cutter can handle the size of your desired acrylic sheets, like a tailor measuring a customer for a perfectly tailored suit.

The sheet material you’ll be working with is acrylic, a versatile and widely used material known for its durability and transparency. Laser technology is the key to achieving precise and clean cuts on acrylic sheets.

When choosing a laser cutter, consider the maximum sheet size it can accommodate. Some laser cutters have a limited working area, so it’s essential to check if it can handle the dimensions of your acrylic sheets.

Additionally, ensure that the laser cutter provides user-friendly features and software for a smoother cutting experience. This will be discussed further in the next section about user-friendly features and software.

Look for User-Friendly Features and Software

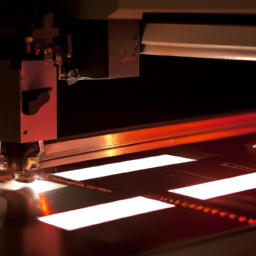

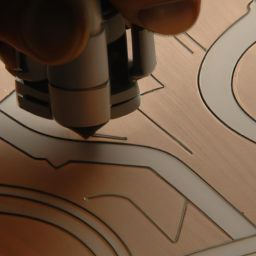

Explore the user-friendly features and intuitive software of the best nd:yag laser cutter to effortlessly cut acrylic sheets. When choosing a laser cutter, it’s crucial to consider the user-friendliness of the machine and the accompanying software. Look for features such as a user-friendly interface, easy-to-navigate menus, and customizable settings.

A laser cutter with intuitive software allows for precise cutting of acrylic sheets with minimal effort. Ensure that the software provides options for adjusting cutting speed and power, as it’ll enable you to achieve optimal cutting precision. Additionally, advanced features like auto-focus and material recognition can further enhance the user experience and streamline the cutting process.

With a laser cutter that offers user-friendly features and powerful software, you can effortlessly cut acrylic sheets to perfection.

Moving on to the next section, it’s important to check for safety features and maintenance requirements to ensure smooth operation.

Check for Safety Features and Maintenance Requirements

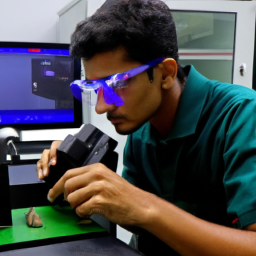

Make sure you keep an eye out for the safety features and maintenance requirements of the laser cutter to ensure a smooth and worry-free operation. Safety precautions are of utmost importance when operating a laser cutter, especially when working with acrylic sheets.

Look for features such as emergency stop buttons, interlock systems, and protective enclosures that prevent accidental exposure to the laser beam. Additionally, consider the availability and ease of obtaining replacement parts, as well as the recommended maintenance schedule and procedures. Regular cleaning and alignment checks are essential for optimal performance and longevity of the machine.

By prioritizing safety and following maintenance tips, you can ensure a reliable and efficient laser cutting experience. Transitioning into the next section about the overall cost and return on investment, it’s important to consider these factors alongside safety and maintenance.

Consider the Overall Cost and Return on Investment

When considering which laser cutter to invest in, it’s important to take into account the overall cost and how it will pay off in the long run.

One crucial aspect to consider is the maintenance costs associated with the laser cutter. Different models may require varying levels of maintenance, and it’s essential to evaluate the potential expenses involved.

Additionally, it is vital to calculate the potential productivity gains that the laser cutter can offer. A high-quality Nd:YAG laser cutter can significantly increase productivity by providing quick and precise cuts on acrylic sheets. By investing in a laser cutter that offers efficient cutting speeds and accuracy, you can save time and increase production output, ultimately leading to a higher return on investment.

It’s crucial to carefully consider the overall cost and potential gains before making a decision.

Frequently Asked Questions

How does the Nd:YAG laser technology compare to other laser cutting technologies?

When comparing Nd:YAG laser technology to CO2 laser technology, there are notable differences. The Nd:YAG laser operates at a shorter wavelength, allowing for more precise and intricate cuts. It is particularly advantageous for precision cutting due to its ability to deliver high energy pulses in a short amount of time.

The Nd:YAG laser cutter is ideal for applications where accuracy and fine detail are crucial, making it a top choice for cutting acrylic sheets.

Can the Nd:YAG laser cutter also cut materials other than acrylic sheets?

The Nd:YAG laser cutter offers several advantages for cutting acrylic sheets. It provides high precision and smooth cuts, ensuring excellent edge quality. Additionally, it is capable of cutting a wide range of materials other than acrylic sheets. This includes metals such as stainless steel and aluminum, as well as various plastics, ceramics, and even certain composites. Its versatility makes it a valuable tool for various industries requiring precise and efficient material cutting.

Is it possible to upgrade the power and wattage options of the Nd:YAG laser cutter in the future?

Yes, it’s possible to upgrade the power and wattage options of the nd:yag laser cutter in the future. This allows for increased cutting capabilities and versatility. Power and wattage upgrades offer the ability to cut through thicker materials or achieve faster cutting speeds.

Upgrading the laser cutter’s power and wattage ensures that it can adapt to changing needs and advancements in technology, making it a more efficient and effective tool for various applications.

What is the maximum size of acrylic sheets that the cutting bed can accommodate?

The maximum size of acrylic sheets that the cutting bed of an Nd:YAG laser cutter can accommodate depends on the specific machine model. However, Nd:YAG laser technology offers several advantages for cutting acrylic sheets. Its high power density and small focused spot size allow for precise and clean cuts, while its non-contact nature eliminates the need for clamping or fixing the material. Additionally, Nd:YAG lasers can cut through thicker acrylic sheets compared to other laser technologies.

Are there any specific safety features or maintenance requirements that need to be considered for the Nd:YAG laser cutter?

To ensure safe operation and optimal performance of the nd:YAG laser cutter, several safety precautions and maintenance requirements must be considered.

Safety measures include wearing protective eyewear to shield eyes from laser radiation, implementing proper ventilation systems to remove fumes, and ensuring the laser cutter is operated in a controlled environment.

Regular maintenance tasks involve cleaning the optics, checking for any loose or damaged parts, and calibrating the laser for accurate cutting.

Using nd:YAG laser technology offers benefits such as precise and clean cuts, minimal material wastage, and efficient processing of acrylic sheets.

Conclusion

So there you have it, the best Nd:YAG laser cutter for cutting acrylic sheets. With its numerous benefits and powerful wattage options, as well as its spacious cutting bed size, this laser cutter is sure to meet all your needs.

Not to mention its user-friendly features and software that make operating it a breeze. And let’s not forget about the safety features and maintenance requirements that ensure a long lifespan.

While the initial investment may seem steep, the overall cost and return on investment make it well worth it. Don’t miss out on this top-notch laser cutter—it’s the cutting-edge technology you’ve been waiting for.