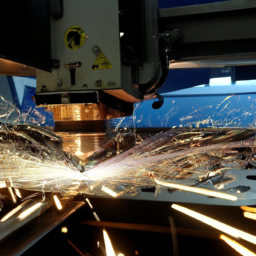

Did you know that a staggering 90% of laser cutting quality issues are caused by using the wrong blade?

When it comes to achieving clean and smooth cuts, choosing the right subtractive laser cutting blade is crucial. With so many options available, it can be overwhelming to find the best one for your needs. But worry not, because we’ve done the research for you.

In this article, we will explore the top-notch subtractive laser cutting blades that will revolutionize your cutting experience. From diamond-coated blades that offer unmatched precision to tungsten carbide blades known for their durability, we’ve got you covered. We will also delve into ceramic blades, stainless steel blades, titanium nitride coated blades, and zirconium nitride coated blades.

So, whether you’re a professional or a hobbyist, get ready to discover the ultimate laser cutting blades that will ensure flawless results every time.

Key Takeaways

- Diamond-coated blades offer unmatched precision and are suitable for cutting tough materials.

- Tungsten carbide blades provide high precision and sharpness, making them suitable for various materials.

- Stainless steel blades are durable, cost-effective, and deliver clean, smooth cuts.

- Titanium nitride and zirconium nitride coated blades provide excellent durability, heat resistance, and superior hardness, resulting in clean, smooth cuts.

Diamond-Coated Blades

When it comes to achieving clean, smooth cuts, nothing beats the unbeatable precision and undeniable power of diamond-coated blades. The advantages of diamond-coated blades are numerous. Firstly, the diamond coating provides exceptional hardness, allowing the blade to effortlessly slice through even the toughest materials like steel or ceramics. This results in cleaner cuts with minimal chipping or splintering.

Secondly, the diamond coating creates a smooth cutting surface, reducing friction and heat buildup, which can lead to warping or melting of the material being cut. However, diamond-coated blades also have their limitations. They tend to be more expensive than other types of blades, making them less accessible for some users. Additionally, the diamond coating can wear off over time, reducing the blade’s effectiveness.

Transitioning into the subsequent section about tungsten carbide blades, these blades offer their own unique set of advantages.

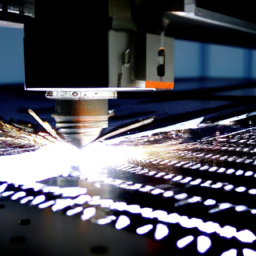

Tungsten Carbide Blades

Tungsten Carbide Blades are known for their high precision and sharpness, making them a top choice for many industries. These blades are designed to provide clean and accurate cuts with minimal effort.

Additionally, they are suitable for cutting various materials, including metals, plastics, and wood, making them versatile and practical for a wide range of applications.

High Precision and Sharpness

Although diamond blades are known for their high precision and sharpness, it’s interesting to note that they can achieve cutting speeds of up to 30 times faster than traditional blades. This makes them a top choice for those seeking both accuracy and efficiency in their laser cutting projects.

Not only do diamond blades offer exceptional speed, but they also require minimal blade maintenance, ensuring longevity and cost-effectiveness. Here are five reasons why diamond blades are a great option for clean and smooth cuts:

- Exceptional hardness and durability

- Reduced heat generation during cutting

- Minimal material wastage

- Ability to cut through various thicknesses

- Versatility for cutting a wide range of materials

With these advantages, diamond blades are suitable for various materials, making them a go-to option for professionals in need of precise and efficient laser cutting.

Suitable for Various Materials

Diamond blades offer the advantage of being highly versatile, allowing you to effectively cut through a wide range of materials with precision and efficiency. When it comes to laser cutting blade maintenance, there are a few important tips to keep in mind.

First, make sure to clean the blade regularly to remove any debris or residue that may affect its performance. Additionally, check the blade for any signs of wear or damage, and replace it if necessary to ensure optimal cutting results.

When selecting a laser cutting blade, consider factors such as the type of material you’ll be cutting, the thickness of the material, and the desired cutting speed. By considering these factors and following proper maintenance practices, you can ensure that your diamond blade will continue to deliver clean and smooth cuts.

Now let’s move on to discussing ceramic blades.

Ceramic Blades

For the cleanest, smoothest cuts, you’ll want to consider using ceramic blades. Imagine effortlessly slicing through delicate materials like paper or fabric, leaving behind precise edges without any fraying or tearing.

Ceramic blades offer several advantages that make them a great choice for subtractive laser cutting. Firstly, they’re extremely sharp and durable, ensuring that you can achieve consistent and accurate cuts over time. Additionally, ceramic blades are non-conductive, making them ideal for cutting materials that may be sensitive to heat.

However, it’s important to note that ceramic blades may not be suitable for cutting harder or thicker materials, as they can be prone to chipping or breaking.

Now, let’s move on to the next section and explore the benefits of stainless steel blades.

Stainless Steel Blades

Now that you’ve learned about ceramic blades, let’s move on to another option for the best subtractive laser cutting blades: stainless steel blades. These blades are known for their durability and ability to deliver clean, smooth cuts.

With a stainless steel blade, you can expect it to last for a long time, making it a cost-effective choice for your laser cutting needs. Plus, maintenance is a breeze – simply wipe the blade clean after each use to keep it in optimal condition.

When it comes to stainless steel blades, there are a few key factors to consider, such as the blade’s thickness, tooth count, and overall design. These aspects will determine the blade’s performance and the type of materials it can cut through effectively.

Next, we’ll explore another option for the best subtractive laser cutting blades: titanium nitride coated blades. But first, let’s dive into the details of why these blades are a top choice for many professionals.

Titanium Nitride Coated Blades

If you want to take your laser cutting to the next level, titanium nitride coated blades are the way to go – they’ll revolutionize your cutting experience! The advantages of using titanium nitride coated blades in laser cutting are numerous.

Firstly, the coating increases the hardness of the blade, making it more resistant to wear and tear. This means that the blade will last longer, reducing the need for frequent blade replacements.

Secondly, titanium nitride coating reduces friction, allowing for smoother and cleaner cuts. The coating also acts as a heat barrier, preventing the blade from overheating during the cutting process.

The process of applying titanium nitride coating to laser cutting blades involves depositing a thin layer of titanium nitride onto the surface of the blade using a physical vapor deposition method. This creates a strong and durable coating that enhances the performance of the blade.

With the advantages offered by titanium nitride coated blades, it’s clear why they are highly recommended in laser cutting.

Moving on to the next section about zirconium nitride coated blades, you’ll discover another excellent option for achieving superior cutting results.

Zirconium Nitride Coated Blades

Explore the potential benefits of using zirconium nitride coated blades for an upgraded laser cutting experience. The advantages of zirconium nitride coating make it a top choice among laser cutting enthusiasts.

Compared to other coatings, zirconium nitride offers excellent durability, ensuring that the blades can withstand the rigors of laser cutting for extended periods. Additionally, this coating provides enhanced heat resistance, preventing the blades from overheating during the cutting process.

The zirconium nitride coating also reduces friction, resulting in smoother and cleaner cuts. When compared to other coatings such as titanium nitride, zirconium nitride demonstrates superior performance in terms of hardness and wear resistance.

So, if you want clean and smooth cuts, zirconium nitride coated blades are the way to go.

Frequently Asked Questions

Can these laser cutting blades be used on different types of materials, such as wood or plastic?

Yes, these laser cutting blades can be used on different types of materials, including wood and plastic. When choosing laser cutting blades for different applications, it’s important to consider the unique requirements of each material. Factors to consider include the material’s thickness, density, and heat sensitivity.

By selecting the right blade, you can achieve clean and smooth cuts on a variety of materials, ensuring optimal results for your laser cutting projects.

What is the average lifespan of these laser cutting blades before they need to be replaced?

The lifespan of laser cutting blades can vary depending on several factors. Laser cutting blade longevity is influenced by factors such as the type of material being cut, the thickness of the material, the speed of the cutting process, and the maintenance of the blade.

On average, laser cutting blades can last anywhere from several months to a couple of years before they need to be replaced. It’s important to regularly inspect and maintain the blades to ensure optimal performance and longevity.

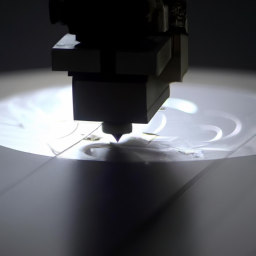

Are there any specific safety precautions that need to be taken when using these laser cutting blades?

When it comes to using laser cutting blades, safety should be your top priority. Imagine you’re a tightrope walker, carefully balancing on a thin wire. In the same way, handling laser cutting blades requires precision and caution.

Always wear protective goggles and gloves to shield yourself from sparks and debris. Avoid using damaged or dull blades, as they can cause accidents.

Never forget to secure your workpiece properly, and be mindful of flammable materials nearby.

Stay safe and cut with confidence!

Can these blades be sharpened or do they need to be replaced once they become dull?

You can sharpen these laser cutting blades instead of replacing them once they become dull. This option is cost-effective as it allows you to extend the lifespan of the blades. Sharpening the blades ensures that they maintain their effectiveness in delivering clean and smooth cuts.

By regularly sharpening the blades, you can save money in the long run and continue to achieve high-quality results.

Are there any specific maintenance requirements for these laser cutting blades to ensure optimal performance?

To ensure optimal performance, laser cutting blades require regular maintenance. By properly maintaining these blades, you can enjoy the benefits of clean and smooth cuts on various materials.

Regular cleaning is essential to remove any debris or residue that may hinder the blade’s performance. Additionally, it’s important to check and replace any worn or damaged parts to maintain the blade’s efficiency.

Following these maintenance requirements will help you achieve the best results with your laser cutting blades.

Conclusion

So there you have it, the best subtractive laser cutting blades for clean, smooth cuts.nnWith diamond-coated blades, tungsten carbide blades, ceramic blades, stainless steel blades, titanium nitride coated blades, and zirconium nitride coated blades, you have a wide range of options to choose from.nnThese blades are like the artists’ brushes, delicately sculpting your materials with precision and finesse.nnSo go ahead, let your creativity soar as you embark on your next laser cutting project with these top-notch blades.