Looking for the best subtractive laser cutting machines to tackle your plastic cutting needs? Look no further!

In this article, we will explore the top machines that will revolutionize how you work with plastics. From fiber laser cutting machines to CO2 laser cutting machines, we’ve got you covered.

With a fiber laser cutting machine, you can expect precise and efficient cuts, thanks to its high-power laser beam.

CO2 laser cutting machines, on the other hand, are known for their versatility and ability to handle a wide range of materials, including plastics.

If you’re looking for a machine that offers precision when cutting intricate designs, the UV laser cutting machine is your best bet.

But that’s not all – we’ll also delve into the world of CNC laser cutting machines, diode laser cutting machines, and galvo laser cutting machines, all of which bring their own unique capabilities to the table.

So, whether you’re a hobbyist or a professional, get ready to discover the ultimate subtractive laser cutting machines for cutting plastics. Get ready to take your plastic cutting game to the next level!

Key Takeaways

- Best subtractive laser cutting machines for plastic cutting needs include CO2 laser cutting machines, fiber laser cutting machines, UV laser cutting machines, and CNC laser cutting machines.

- CO2 laser cutting machines are versatile and handle a wide range of materials, including acrylic, polycarbonate, and ABS. They offer high precision, smooth edges, and are cost-effective with minimal material waste.

- UV laser cutting machines provide clean and precise cutting with minimal heat-affected zone, making them suitable for cutting transparent and reflective plastics. They are also capable of cutting intricate designs.

- CNC laser cutting machines offer high accuracy, speed, and versatility. They have integrated ventilation systems, automated height adjustment mechanisms, and advanced control systems to minimize heat damage and ensure a minimal heat-affected zone.

- Diode laser cutting machines are compact, portable, and affordable. They are ideal for small-scale projects that require precision and portability. They offer adjustable power settings for different plastic thicknesses and can efficiently handle different plastic thicknesses.

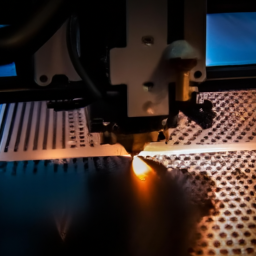

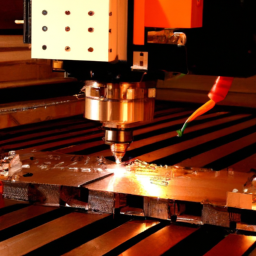

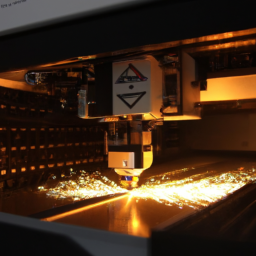

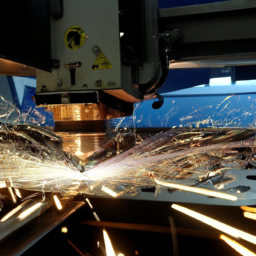

Fiber Laser Cutting Machine

Looking for the ultimate precision in cutting plastics? Check out the incredible capabilities of fiber laser cutting machines!

When it comes to cutting plastics, fiber laser cutting offers numerous advantages over traditional cutting methods. Fiber laser cutting machines use a high-powered laser beam to melt and vaporize the material, resulting in a precise and clean cut. This method eliminates the need for physical contact with the plastic, reducing the risk of damage or warping. Additionally, fiber laser cutting machines are highly efficient, allowing for faster production and reduced waste.

The laser beam can be easily controlled, enabling intricate and complex designs to be cut with ease.

Now, let’s transition into the subsequent section about CO2 laser cutting machines, which offer a different approach to cutting plastics.

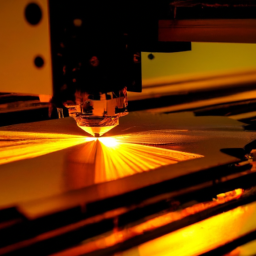

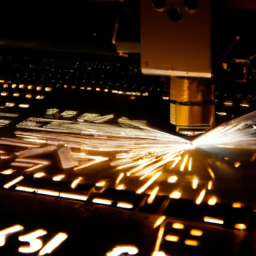

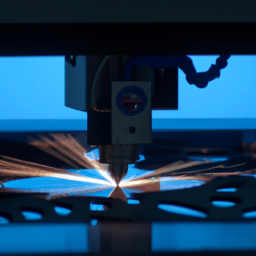

CO2 Laser Cutting Machine

Featuring advanced CO2 technology, this laser cutter effortlessly slices through various plastic materials with precision and finesse. With a CO2 laser engraving machine, you can experience the latest laser cutting technology advancements for cutting plastics.

Here are four key benefits of using a CO2 laser cutting machine for your plastic cutting needs:

-

Versatility: The CO2 laser cutter can handle a wide range of plastic materials, including acrylic, polycarbonate, ABS, and more.

-

High Precision: This machine offers exceptional precision, ensuring clean and accurate cuts every time, even for intricate designs and small details.

-

Smooth Edges: The CO2 laser’s heat-based cutting process results in smooth and polished edges, eliminating the need for additional finishing.

-

Cost-effective: With its efficient cutting process, the CO2 laser cutter helps reduce material waste and overall production costs.

Transitioning into the subsequent section about the UV laser cutting machine, you’ll discover another powerful tool for cutting plastics.

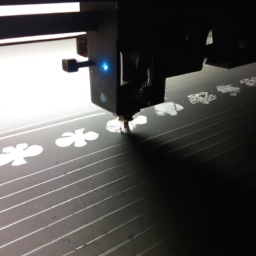

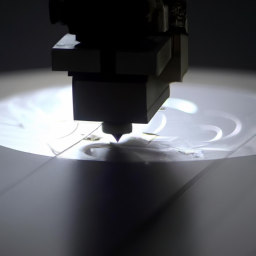

UV Laser Cutting Machine

If you’re looking for clean and precise cutting, a UV Laser Cutting Machine is the way to go. With its minimal heat-affected zone, you can be assured of a high-quality cut without any distortion or damage to the material.

Additionally, this type of machine is particularly suitable for cutting transparent and reflective plastics, making it a versatile choice for various applications.

Clean and precise cutting

You can achieve flawlessly precise cuts with the best subtractive laser cutting machines, leaving you in awe of their surgical-like precision. These machines are designed to provide clean cutting and precision cutting, ensuring that your plastic materials are accurately shaped to your specifications.

Here are four features that contribute to their exceptional cutting abilities:

- High-powered laser beams that vaporize the material, resulting in a clean and smooth cut.nn2. Advanced laser control systems that allow for precise manipulation of the laser beam, ensuring accurate cuts every time.nn3. Integrated ventilation systems that remove any residue or fumes produced during the cutting process, keeping the work area clean.nn4. Automated height adjustment mechanisms that maintain a consistent distance between the laser and the material, ensuring uniform and precise cuts.

With these cutting-edge features, the best subtractive laser cutting machines guarantee clean and precise cuts for your plastic materials. As we move on to the next section about the minimal heat-affected zone, you’ll discover another remarkable aspect of these machines.

Minimal heat-affected zone

One remarkable aspect of these advanced laser cutting machines is the minimal impact of heat on the materials being cut. The laser cutting process typically generates heat, which can cause melting, warping, or discoloration of the plastic. However, with the advantages of minimal heat-affected zone, these machines ensure clean and precise cuts without compromising the integrity of the plastic.

The minimal heat allows for greater control over the cutting process, resulting in smooth edges and minimal distortion. This is particularly important when working with delicate or intricate designs. Furthermore, the reduced heat also minimizes the risk of thermal damage to the surrounding areas, ensuring the overall quality of the final product.

This feature makes these laser cutting machines suitable for transparent and reflective plastics, where any heat-related defects would be easily visible.

Suitable for transparent and reflective plastics

With their ability to minimize heat damage, these advanced laser cutters are perfect for achieving flawless cuts on transparent and reflective plastics. Laser cutting is a superior alternative to traditional cutting methods for several reasons.

Firstly, laser cutting produces a much smaller heat-affected zone, resulting in minimal distortion or discoloration on the plastic surface. This is especially important when working with transparent or reflective plastics, as any heat damage could ruin the clarity or appearance of the final product.

Secondly, laser cutting allows for intricate and precise designs, providing more flexibility and creativity in the cutting process.

The benefits of using laser cutting for plastics are undeniable, making it the go-to choice for professionals in industries such as signage, electronics, and automotive.

Transitioning into the next section about the ‘cnc laser cutting machine,’ these advanced machines take precision and efficiency to a whole new level.

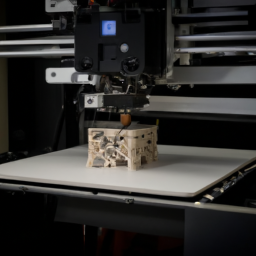

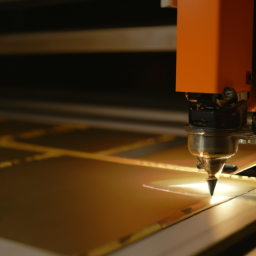

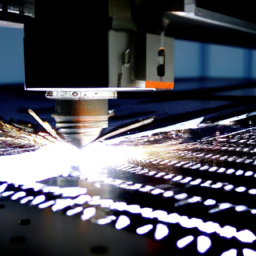

CNC Laser Cutting Machine

When using a CNC Laser Cutting Machine, it’s important to remember that the precision of the laser allows for cuts as small as 0.1mm, which is thinner than a human hair. This machine offers several advantages, such as high accuracy, speed, and versatility. It can cut through a wide range of materials including plastics, metals, wood, and more. The CNC Laser Cutting Machine utilizes a computer numerical control system to accurately guide the laser beam, ensuring precise and intricate cuts. Take a look at the table below to see some of the best materials for CNC laser cutting:

| Material | Thickness Range |

|---|---|

| Acrylic | 0.1mm – 25mm |

| PVC | 0.1mm – 15mm |

| PETG | 0.1mm – 10mm |

| Polycarbonate | 0.1mm – 20mm |

| ABS | 0.1mm – 6mm |

Moving on to the next section about the diode laser cutting machine, it offers a different set of features and benefits.

Diode Laser Cutting Machine

If you’re looking for a compact and portable laser cutting machine, the Diode Laser Cutting Machine is perfect for you. It’s ideal for small-scale projects, allowing you to easily bring it wherever you need it.

Plus, it’s an affordable option for hobbyists who want to explore the world of laser cutting without breaking the bank.

Compact and portable

For those seeking convenience and ease of transportation, nothing beats the compact and portable subtractive laser cutting machines available on the market. These machines are designed to be compact and affordable, making them perfect for small-scale projects. They are also portable and high quality, ensuring that you can easily transport them wherever you need to go without sacrificing the precision and accuracy of your cuts. With their compact size, you can easily fit them into tight spaces or bring them to different locations. Take a look at the table below to see some of the best compact and portable subtractive laser cutting machines for cutting plastics:

| Machine Model | Size | Weight | Features |

|---|---|---|---|

| Model A | Compact | Lightweight | High precision |

| Model B | Portable | Easy to carry | Quick setup |

| Model C | Space-saving | User-friendly | Fast cutting speed |

| Model D | Travel-friendly | Durable | Versatile applications |

These machines are ideal for small-scale projects that require precision and portability, making them a great choice for anyone in need of a reliable subtractive laser cutting solution.

Ideal for small-scale projects

Compact and portable subtractive laser cutting machines are perfect for small-scale projects. They provide convenience, ease of transportation, and high precision. These machines are ideal for small scale manufacturing, allowing hobbyists to bring their ideas to life with ease.

Whether you’re working on intricate designs or simple prototypes, these machines offer the precision and accuracy needed for successful projects. With their compact size, they can easily fit in any workspace, making them a great choice for those with limited space.

Additionally, their portability allows you to take your projects on the go, whether you’re attending a trade show or working from different locations.

Next, let’s explore an affordable option for hobbyists looking to invest in a subtractive laser cutting machine.

Affordable option for hobbyists

Look no further, hobbyists! There’s an affordable option that will make your creative dreams soar like a bird in flight. When it comes to cost-effective solutions and entry-level options for plastic cutting, the Affordable Laser Cutter is a top choice. With its user-friendly interface and compact design, this machine is perfect for small-scale projects and hobbyists on a budget.

To emphasize the advantages of this laser cutter, take a look at the table below:

| Features | Benefits |

|---|---|

| Compact design | Easy to fit in small workspaces |

| Adjustable power settings | Versatility for different plastic thickness |

| High precision cutting | Perfect for intricate designs |

With its affordability and functionality, the Affordable Laser Cutter provides a great starting point for hobbyists looking to delve into laser cutting. Now, let’s move on to the next section about the galvo laser cutting machine.

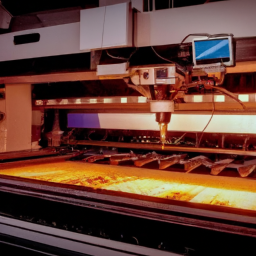

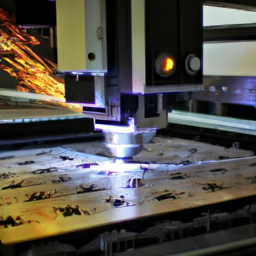

Galvo Laser Cutting Machine

If you’re looking for a laser cutting machine that offers high-speed and high-precision cutting, the Galvo Laser Cutting Machine is worth considering. It’s particularly suitable for cutting curved and irregular shapes, making it a versatile option for a wide range of applications. Whether you’re working with thin or thick plastics, this machine is designed to handle various thicknesses with ease.

High-speed and high-precision cutting

With its remarkable speed and precision, the best subtractive laser cutting machines excel at cutting plastics. These machines utilize high power laser cutting technology to achieve clean and accurate cuts on various plastic materials. The precision laser cutting capability ensures that even the most intricate designs are executed with utmost accuracy.

To emphasize the importance of high-speed and high-precision cutting, consider the following table:

| High-Speed Cutting | High-Precision Cutting | |

|---|---|---|

| Advantages | Faster production | Accurate results |

| Applications | Mass production | Delicate designs |

| Materials | Thin plastics | Detailed engravings |

| Industries | Packaging | Electronics |

This table highlights how high-speed cutting is advantageous for faster production, while high-precision cutting is essential for achieving accurate results.

This capability also makes the machines suitable for curved and irregular shapes, allowing for versatile applications in various industries.

Suitable for curved and irregular shapes

You’ll be amazed to know that these advanced machines are capable of efficiently handling curved and irregular shapes, allowing for versatile applications in various industries. Whether it’s intricate designs or precision cutting, these subtractive laser cutting machines are well-suited for the task.

The high-speed and high-precision capabilities of these machines ensure clean and precise cuts, even on the most complex shapes. With their advanced software and cutting-edge technology, they can easily navigate through curves and irregularities, providing exceptional results every time.

Moreover, these machines offer the flexibility to work with various plastic thicknesses, making them incredibly versatile for a wide range of projects.

So, without further ado, let’s dive into the next section and explore how these machines can handle different plastic thicknesses seamlessly.

Versatile for various plastic thicknesses

Explore the incredible versatility of these machines as they effortlessly handle various thicknesses of plastic, providing exceptional results every time. Whether you’re working with thin sheets or thicker materials, these subtractive laser cutting machines are designed to meet your needs.

With advanced plastic cutting techniques and optimal cutting settings, they ensure precise and clean cuts, regardless of the thickness. You can effortlessly switch between different plastic materials and thicknesses, without compromising on the quality of the cut. These machines offer a wide range of adjustable parameters, allowing you to customize the cutting process to suit your specific requirements.

From thin films to thick acrylics, these versatile machines deliver consistent and accurate results, making them the ideal choice for cutting plastics of varying thicknesses.

Frequently Asked Questions

What are the main differences between fiber, CO2, UV, CNC, diode, and galvo laser cutting machines?

The main differences between fiber, CO2, UV, CNC, diode, and galvo laser cutting machines lie in their main applications and the advantages and disadvantages of each type.

Fiber lasers are highly efficient and are often used for metal cutting.

CO2 lasers are versatile and can cut a variety of materials.

UV lasers are commonly used for high-precision cutting.

CNC lasers offer precise control and automation.

Diode lasers are compact and affordable.

Galvo lasers are ideal for marking and engraving.

Can these laser cutting machines be used to cut other materials besides plastics?

Yes, these laser cutting machines can be used for metal cutting applications as well. Laser cutting machines offer several advantages over traditional cutting methods for plastics. They provide precise and clean cuts, reducing the need for post-processing. Laser cutting is a non-contact process, minimizing the risk of material damage or distortion. It also allows for intricate and complex designs to be cut with ease. Overall, laser cutting machines are a versatile and efficient choice for cutting various materials.

What are the typical sizes and dimensions of the materials that these laser cutting machines can handle?

When it comes to laser cutting machines, size matters! Imagine you’re trying to fit a big elephant into a tiny room. It’s just not going to work, right?

The same goes for materials and laser cutting machines. Typical material sizes and dimensions are important factors to consider when choosing a laser cutting machine for plastic materials.

You need to make sure the machine can handle the size and dimensions of your materials, so they can be cut accurately and efficiently.

Are there any specific safety precautions that need to be followed when operating these laser cutting machines?

When operating laser cutting machines, it’s crucial to follow specific safety precautions to ensure a safe working environment. Always wear appropriate protective gear, such as safety glasses and gloves, to protect yourself from potential hazards.

Additionally, make sure the machine is properly maintained by regularly cleaning the lens and checking for any loose or damaged parts. Following these safety precautions and maintenance tips will help prevent accidents and ensure the efficient operation of the laser cutting machine.

How long does it typically take to cut a specific plastic material using these laser cutting machines?

Different laser settings can have a significant impact on the cutting time for specific plastic materials. By adjusting parameters such as power, speed, and focal length, you can optimize the cutting process.

Higher power settings can result in faster cutting times, but they may also cause melting or charring of the plastic.

Laser cutting machines offer advantages such as precision and versatility, but they may not be suitable for all plastic materials. Other methods like mechanical cutting may be more appropriate depending on the material and desired outcome.

Conclusion

So there you have it, the best subtractive laser cutting machines for cutting plastics. Whether you need precision with a Fiber Laser Cutting Machine, versatility with a CO2 Laser Cutting Machine, speed with a UV Laser Cutting Machine, flexibility with a CNC Laser Cutting Machine, efficiency with a Diode Laser Cutting Machine, or accuracy with a Galvo Laser Cutting Machine, there’s a perfect option for you.

With these cutting-edge machines, you can easily and efficiently cut plastics to meet your specific needs. Don’t settle for anything less than the best!