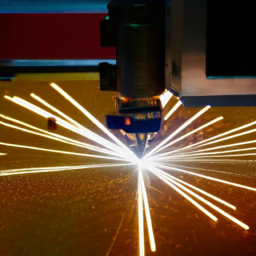

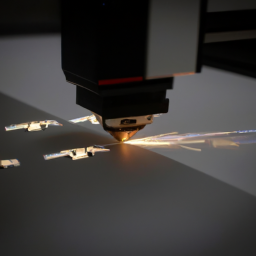

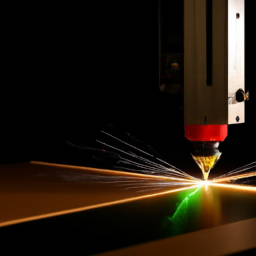

Imagine you’re a skilled craftsman, meticulously carving intricate designs into a block of wood. Now, picture yourself effortlessly etching those same designs onto various materials with the precision and speed of a CO2 laser cutter.

This powerful tool has become a staple for DIY enthusiasts, offering a wide range of possibilities for your projects. In this article, we will explore the pros and cons of owning a CO2 laser cutter for your DIY endeavors.

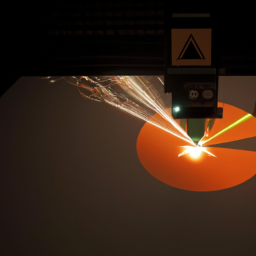

With its precision cutting abilities, a CO2 laser cutter allows you to create intricate designs with unparalleled accuracy. From engraving delicate patterns on jewelry to cutting precise shapes in acrylic, this tool opens up a world of possibilities for your creativity. Additionally, its versatility extends beyond just cutting and engraving. With the right settings, you can also etch, mark, and even weld various materials.

However, owning a CO2 laser cutter comes with its fair share of considerations. The initial investment and maintenance costs can be substantial, making it a decision that requires careful financial planning. Safety should also be a top priority, as lasers can pose serious risks if not handled properly. Finally, it’s important to acknowledge the learning curve and skill development required to effectively operate this tool.

So, let’s dive into the details and uncover whether a CO2 laser cutter is the right choice for your DIY projects.

Key Takeaways

- Precision cutting abilities with unparalleled accuracy

- Versatility in cutting and engraving various materials

- Increased efficiency and productivity with faster cutting speed

- Potential hazards include toxic fumes, eye damage, and burns

Precision Cutting Abilities

One of the major advantages of owning a CO2 laser cutter is its remarkable precision cutting abilities. This allows you to achieve intricate designs with ease. The laser engraving feature of the CO2 laser cutter ensures that your cuts are clean and precise, resulting in professional-looking finished products.

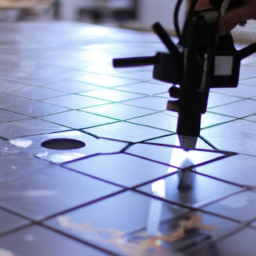

Whether you’re working with wood, acrylic, leather, or even fabric, the CO2 laser cutter offers excellent material compatibility. This ensures that you can achieve precise cuts on a wide range of materials. This versatility gives you the freedom to explore various DIY projects and create intricate designs with precision.

Furthermore, the CO2 laser cutter’s ability to cut through thick materials with ease adds to its precision cutting capabilities. With such precision, the CO2 laser cutter opens up a world of possibilities for your DIY projects, making it an essential tool for any hobbyist or professional.

Versatile Applications

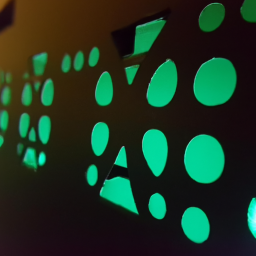

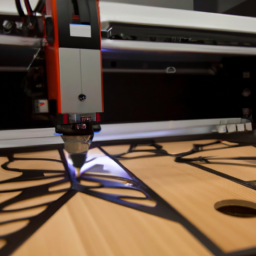

With a CO2 laser cutter, you can customize and personalize a wide range of items to suit your specific needs. Whether it’s engraving your name on a piece of jewelry or adding intricate designs to a phone case, the possibilities are endless.

Additionally, the precision cutting abilities of a CO2 laser cutter make it an excellent tool for woodworking projects, allowing you to make clean and accurate cuts with ease.

So, whether you’re a DIY enthusiast or a professional craftsman, a CO2 laser cutter can be a valuable addition to your arsenal of tools.

Customize and personalize various items

Transforming everyday objects into unique creations is as simple as wielding a CO2 laser cutter, breathing life into ordinary items with a touch of personalized magic. With this powerful tool, you can customize and personalize various items, allowing you to create personalized gifts and DIY home decor. The possibilities are endless as you unleash your creativity and bring your imagination to life.

Here are five ways a CO2 laser cutter can help you personalize your projects:

-

Engrave names, dates, or special messages on jewelry, keychains, or photo frames to create meaningful gifts.

-

Add intricate designs and patterns to wooden furniture, mirrors, or wall art for a one-of-a-kind touch.

-

Personalize glassware, such as wine glasses or mugs, with monograms or custom designs.

-

Create unique signage for events, parties, or businesses with precise laser-cut lettering and logos.

-

Customize leather accessories, like wallets or belts, with embossed patterns or initials.

By harnessing the power of a CO2 laser cutter, you can unleash your artistic side and make precise cuts for woodworking projects, taking your DIY endeavors to the next level.

Make precise cuts for woodworking projects

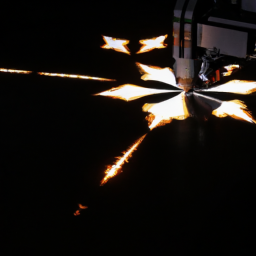

Crafting intricate designs and achieving unparalleled precision, a CO2 laser cutter empowers you to elevate your woodworking projects to new heights. With its laser cutting techniques, this tool allows you to make precise cuts on various materials, including wood, with utmost accuracy.

The laser beam emitted by the CO2 laser cutter offers a level of precision that is unmatched by traditional cutting methods. It enables you to create intricate patterns, delicate engravings, and precise joints, enhancing the overall quality and aesthetics of your woodworking projects. Whether you’re working on furniture, cabinetry, or decorative pieces, the precision woodworking capabilities of a CO2 laser cutter ensure that every cut is clean and precise.

This level of accuracy not only saves you time and effort but also ensures that your woodworking projects have a professional finish. Transitioning into the subsequent section about ‘increased efficiency and productivity,’ utilizing a CO2 laser cutter allows you to take your DIY projects to the next level.

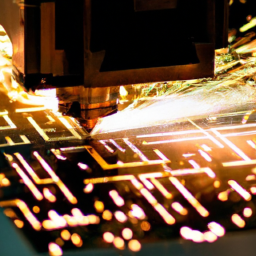

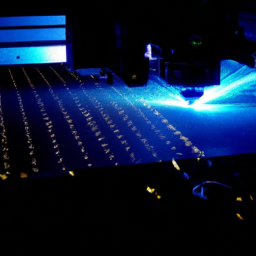

Increased Efficiency and Productivity

Boost your output and get more done in less time by adding a CO2 laser cutter to your DIY arsenal. Here are four reasons why increased efficiency and productivity are key advantages of owning a CO2 laser cutter:

-

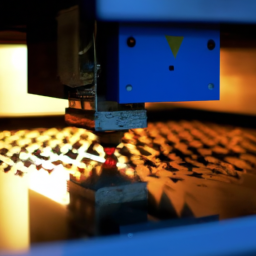

Increased Speed: With a CO2 laser cutter, you can cut through materials at a much faster rate compared to traditional methods. This means you can complete your projects in a fraction of the time, allowing you to move on to your next creative endeavor sooner.

-

Reduced Waste: The precise nature of CO2 laser cutting minimizes material waste. The laser beam provides accurate cuts, reducing the chance of errors or mistakes. This not only saves you money on materials but also contributes to a more sustainable approach to your DIY projects.

-

Versatility: CO2 laser cutters can handle a wide range of materials, including wood, acrylic, fabric, and more. This versatility allows you to work on various projects without the need for different tools, further streamlining your workflow.

-

Increased Productivity: By combining increased speed and reduced waste, a CO2 laser cutter ultimately boosts your overall productivity. You can accomplish more in less time, allowing you to take on more complex projects or increase your output.

Transitioning into the next section about the ‘initial investment and maintenance costs,’ owning a CO2 laser cutter is not only beneficial for efficiency and productivity but also requires careful consideration of its initial investment and maintenance costs.

Initial Investment and Maintenance Costs

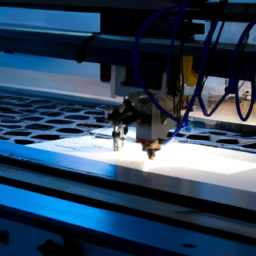

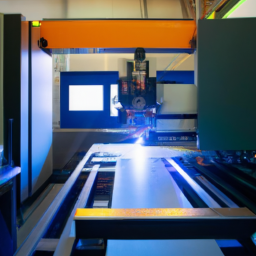

When considering the purchase of a CO2 laser cutter for your DIY projects, you need to take into account the initial investment and maintenance costs.

The upfront cost of purchasing a CO2 laser cutter can vary depending on the specifications and features you require, but it’s important to carefully evaluate your budget and needs.

Additionally, ongoing maintenance and repair expenses should be factored in, as regular maintenance and occasional repairs are necessary to keep your laser cutter in optimal condition for precision and efficiency.

Consider the upfront cost of purchasing a CO2 laser cutter

The initial investment for a CO2 laser cutter may seem steep, but it’s important to consider the long-term benefits. Here are four key points to consider in the upfront cost analysis:

-

Equipment Cost: The price of a CO2 laser cutter can range from a few thousand to tens of thousands of dollars, depending on the size and capabilities. Take into account your specific needs and budget when making a purchasing decision.

-

Consumables: CO2 laser cutters require various consumables like laser tubes, lenses, and mirrors. These components have a limited lifespan and will need to be replaced periodically, adding to the long-term financial implications.

-

Ventilation and Safety: Proper ventilation is crucial to remove harmful fumes generated during the laser cutting process. Installing a ventilation system and ensuring safety measures can add to the upfront cost.

-

Training and Software: Operating a CO2 laser cutter requires training to maximize its potential. Additionally, consider the cost of purchasing or subscribing to software for design and control purposes.

Considering these factors, it’s essential to factor in ongoing maintenance and repair expenses when evaluating the overall cost of owning a CO2 laser cutter.

Factor in ongoing maintenance and repair expenses

Don’t forget to consider the ongoing costs of maintenance and repairs when evaluating the overall expenses of maintaining a CO2 laser cutter. Factor in ongoing maintenance and repair expenses to determine the cost effectiveness of this long term investment. While CO2 laser cutters offer immense versatility and precision for your DIY projects, they require regular upkeep to ensure optimal performance. The table below provides an overview of potential maintenance and repair expenses you may encounter:

| Maintenance/Repair | Frequency | Cost |

|---|---|---|

| Cleaning the lens | Monthly | $20 |

| Replacing the tube | Every 2-3 years | $500 – $1000 |

| Calibrating the machine | Annually | $200 |

| Upgrading software | As needed | Varies |

| Repairing faulty components | Occasional | Varies |

By factoring in these ongoing expenses, you can better assess the long term investment of owning a CO2 laser cutter. Moving forward, it is crucial to also address the safety considerations associated with operating this powerful tool.

Safety Considerations

When using a CO2 laser cutter for your DIY projects, it’s crucial to understand and follow proper safety precautions to ensure your well-being.

Protecting yourself from potential hazards is of utmost importance in order to prevent accidents or injuries.

By adhering to safety guidelines, you can confidently navigate the world of laser cutting and enjoy the creative possibilities it offers.

Understand and follow proper safety precautions

Always remember to wear protective goggles and gloves when operating a CO2 laser cutter, as the intense beam of light can potentially cause eye and skin damage. Safety gear is essential in preventing accidents and protecting yourself from potential hazards.

In addition to wearing goggles and gloves, it’s also important to ensure that you receive proper training on how to operate the laser cutter safely. Many manufacturers offer training programs that teach you how to use the machine correctly and follow proper safety precautions. These programs cover topics such as how to handle the laser cutter, how to set up and adjust the machine, and how to maintain it.

By understanding and following these safety precautions, you can protect yourself from potential hazards and ensure a safe working environment.

Protect yourself from potential hazards

Protecting yourself from potential hazards is like wearing armor that shields you from harm while operating a CO2 laser cutter. Safety precautions are crucial to ensure a safe working environment.

One potential hazard is the emission of toxic fumes, which can be harmful if inhaled. To counter this, it’s essential to have proper ventilation in the workspace, ensuring the fumes are adequately extracted.

Additionally, laser beams can cause severe eye damage, so wearing laser safety glasses is imperative. Avoiding direct exposure to the laser beam and using proper shielding will minimize the risk.

Lastly, the high temperatures generated by the laser can lead to burns, so wearing appropriate protective clothing is necessary.

By implementing these safety precautions, you can mitigate potential hazards and operate the CO2 laser cutter safely. Transitioning to the subsequent section, learning the ins and outs of this machine requires time and practice.

Learning Curve and Skill Development

Mastering the art of operating a CO2 laser cutter can be a challenging yet rewarding journey for DIY enthusiasts. The learning process involves developing various skills that will enable you to create intricate designs with precision. As with any new skill, there’s a learning curve involved, but with practice and dedication, you’ll become proficient in no time.

Here are five key aspects of the learning process:

- Familiarizing yourself with the software and controls to effectively control the laser cutter.

- Understanding the different materials and their compatibility with the laser cutter.

- Learning how to optimize settings for different projects to achieve desired results.

- Mastering the techniques for proper alignment and positioning of materials.

- Acquiring knowledge about maintenance and troubleshooting to ensure smooth operation.

Embarking on this journey won’t only enhance your creativity but also equip you with valuable skills that can be applied to various DIY projects.

Frequently Asked Questions

Is it possible to achieve intricate and delicate cuts with a CO2 laser cutter?

Achieving intricate and delicate cuts with a CO2 laser cutter is a breeze, like a skilled surgeon wielding a scalpel. The advantages of this technology lie in its precision and accuracy, allowing you to create complex designs with ease.

However, it’s important to note the limitations. CO2 laser cutters may struggle with very thick or dense materials, and intricate cuts may take longer to complete. Nonetheless, for most DIY projects, a CO2 laser cutter will exceed your expectations.

What are some unique and creative DIY projects that can be done with a CO2 laser cutter?

With a CO2 laser cutter, you can embark on a world of unique DIY projects and unleash your creativity. The precision and versatility of this tool allow for endless possibilities.

Create intricate and detailed designs on various materials such as wood, acrylic, and leather. Personalize items like jewelry, home decor, and custom gifts.

Explore the realms of signage, model making, and even fabric cutting. The CO2 laser cutter opens doors to countless innovative and imaginative applications.

How does owning a CO2 laser cutter improve efficiency and productivity compared to traditional cutting methods?

Owning a CO2 laser cutter is truly a game-changer when it comes to efficiency and productivity in your DIY projects. Compared to traditional cutting methods, the benefits of using a CO2 laser cutter are unparalleled.

With its precise cutting capabilities and high-speed operation, you can effortlessly breeze through your projects with utmost precision. Say goodbye to time-consuming manual cutting and embrace the future of DIY with a CO2 laser cutter.

What is the average initial investment required to purchase a CO2 laser cutter for DIY projects?

The average initial investment required to purchase a CO2 laser cutter for DIY projects can vary depending on the model and specifications. On average, you can expect to spend anywhere from $3,000 to $10,000.

It’s important to consider additional costs such as ventilation systems, materials, and software. Maintenance requirements typically involve regular cleaning and alignment checks, as well as occasional replacement of consumable parts like lenses and mirrors.

Are there any specific safety precautions or guidelines that need to be followed when using a CO2 laser cutter for DIY projects?

When using a CO2 laser cutter for DIY projects, it’s crucial to follow specific safety precautions. Always wear protective eyewear to shield your eyes from the intense laser beam.

Ensure proper ventilation in the working area to minimize exposure to harmful fumes.

Additionally, never leave the machine unattended during operation and keep flammable materials away from the cutter.

Despite these safety measures, the benefits of using a CO2 laser cutter for intricate cuts are undeniable.

Conclusion

In conclusion, owning a CO2 laser cutter for your DIY projects can be both rewarding and challenging. The precision cutting abilities and versatile applications make it a valuable tool for creating intricate designs. Additionally, the increased efficiency and productivity can save you time and effort.

However, it’s important to consider the initial investment and maintenance costs, as well as the safety considerations associated with operating a laser cutter. Remember, like any skill, there’s a learning curve involved, but with practice and dedication, you can master the art of laser cutting.

So, go ahead and unleash your creativity with a CO2 laser cutter!