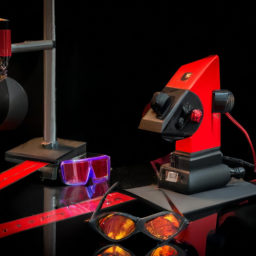

Are you tired of struggling to cut through thick materials with traditional cutting methods? Well, prepare to have your mind blown! We present to you the top 5 designs for laser cutting that will effortlessly slice through even the thickest of materials.

These designs are like super-powered superheroes, armed with the precision and power to make your cutting tasks a breeze. From the sleek and straight lines to the elegantly curved patterns, these laser cutting designs will have you wondering why you didn’t discover them sooner.

And let’s not forget about the lattice design, a true work of art that combines strength and beauty. But wait, there’s more! The geometric and interlocking designs will leave you in awe of their ingenuity, while the perforated design takes cutting to a whole new level.

So, get ready to revolutionize your cutting experience with these top 5 laser cutting designs for cutting thick materials.

Key Takeaways

- Laser cutting designs for cutting thick materials can be categorized into straight line designs for precise and efficient cuts, and curved designs for intricate shapes.

- Laser cutting offers high precision and clean cuts, making it a versatile and time-efficient method in various industries such as industrial manufacturing, art, and design.

- Laser cutting has specific uses in jewelry making, model making, fashion design, industrial manufacturing, engraving on gemstones, and creating customized pens.

- Laser cutting has the capability to achieve a precision of up to 0.1mm, create complex parts, prototypes, and molds, add a unique touch to garments and accessories, allow for intricate metal cutouts in jewelry making, and create detailed miniature figures in model making.

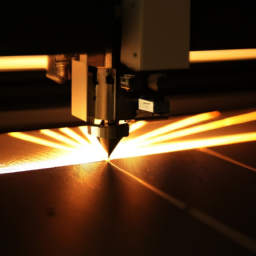

Straight Line Design

Straight line designs are the go-to choice when it comes to laser cutting thick materials. They allow for precise and efficient cuts. These designs are characterized by their simplicity and clean lines, making them perfect for creating straight line art and minimalist designs.

Laser cutting machines can easily follow these straight lines, resulting in accurate and smooth cuts through thick materials like wood, acrylic, or metal. Whether you’re creating intricate patterns or cutting out large shapes, straight line designs offer a straightforward and effective solution.

However, if you’re looking for more complex and dynamic designs, the next section will explore the beauty of curved designs and how they can enhance the laser cutting process.

Curved Design

If you’re looking to create intricate shapes in thick materials, curved designs are perfect for the job.

With their smooth and flowing lines, these designs allow for precise cutting and detailing.

They also have applications in artistic and decorative projects, adding an elegant touch to any creation.

Perfect for Creating Intricate Shapes in Thick Materials

When you’re looking to create intricate shapes in thick materials, laser cutting offers a perfect solution. Laser cutting technology has numerous applications in industrial manufacturing, thanks to its precision and versatility. Here are four benefits of laser cutting for cutting thick materials:

-

High precision: Laser cutting allows for incredibly precise cuts, enabling you to create intricate shapes with ease.

-

Clean cuts: The laser beam melts and vaporizes the material as it cuts, resulting in clean edges without any burrs or roughness.

-

Versatility: Laser cutting machines can work with a wide range of materials, including metals, plastics, and wood, making it suitable for various projects.

-

Time-efficient: Laser cutting is a fast process, allowing for quick production of intricate shapes in thick materials.

With these advantages, laser cutting is not only ideal for industrial manufacturing but also finds applications in artistic and decorative projects. It seamlessly transitions into the subsequent section, highlighting its versatility beyond industrial settings.

Applications in Artistic and Decorative Projects

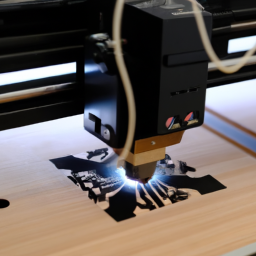

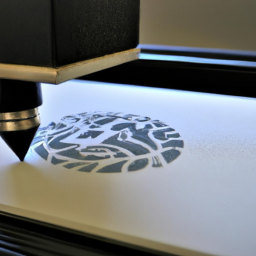

The versatility of laser cutting technology extends beyond industrial manufacturing – it unlocks endless creative possibilities in the world of art and design. When it comes to artistic and decorative projects, laser cutting offers a wide range of customization options.

Whether you want to create intricate patterns or unique shapes, laser cutting allows you to bring your artistic vision to life with precision and accuracy. Moreover, laser cutting can serve functional purposes in artistic projects by cutting through thick materials.

For example, you can use laser cut pieces to construct durable and visually appealing furniture or decorative elements. The ability to cut through thick materials opens up a whole new world of possibilities for artists and designers alike.

Speaking of which, one popular design technique in laser cutting for thick materials is the lattice design…

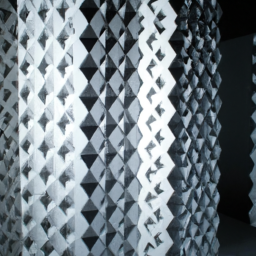

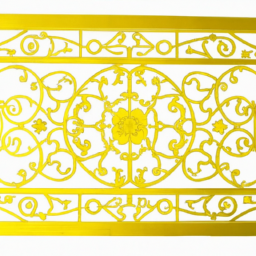

Lattice Design

In lattice design, you’ll explore how it provides structural support and reduces material waste. This design technique is widely used in architecture and engineering due to its ability to distribute weight evenly and efficiently.

By incorporating a lattice structure, you can create stronger and more durable structures while minimizing the amount of material needed.

Provides Structural Support and Reduces Material Waste

By incorporating structural support and minimizing material waste, these laser-cut designs create a visually striking and efficient solution for cutting thick materials. The lattice design, with its intricate interwoven pattern, not only provides structural integrity but also reduces material usage, making it a cost-effective option. The use of a lattice structure allows for the dispersion of stress throughout the material, ensuring its strength and durability. Additionally, the lattice design allows for the removal of excess material, resulting in a lighter and more efficient end product. When laser cutting thick materials, such as metals or wood, the lattice design offers a balance between strength and weight, making it an ideal choice for various applications in architecture and engineering. This design’s versatility and efficiency make it a popular choice among designers and manufacturers in these industries.

Applications in Architecture and Engineering

Now let’s explore the exciting applications of laser cutting in architecture and engineering.

With its ability to precisely cut through thick materials, laser cutting has revolutionized the construction industry. Architects and engineers can now create intricate designs and complex structures that were once thought impossible. From cutting steel beams for skyscrapers to crafting intricate facades, laser cutting offers endless possibilities in construction.

Moreover, the benefits extend beyond design aesthetics. Laser cutting provides cost-effective solutions for manufacturing components with high precision and accuracy. It reduces material waste and allows for efficient production processes.

As we delve into the next section on geometric design, you’ll discover how this technique further enhances the versatility and functionality of laser cutting.

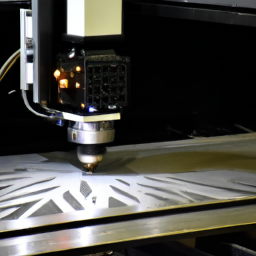

Geometric Design

Geometric Design offers you versatility in cutting complex patterns and designs, allowing you to create intricate and unique pieces. It’s ability to cut precise angles and shapes makes it particularly useful in applications such as jewelry making and model making.

Whether you want to create delicate filigree patterns or intricate architectural models, geometric design is a valuable tool that can bring your creative vision to life.

Offers Versatility in Cutting Complex Patterns and Designs

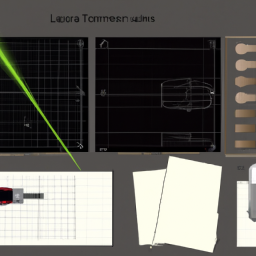

Versatility in cutting complex patterns and designs is a key feature of laser cutting. It allows for intricate and detailed cuts that would be difficult to achieve with other methods. Did you know that laser cutting can achieve a precision of up to 0.1mm? This ensures the accuracy of even the most intricate designs. This precision is made possible through advanced cutting techniques, enabling the laser to follow intricate patterns with utmost accuracy.

Laser cutting offers versatility in industrial manufacturing. It can effectively cut a wide range of materials, including metals, plastics, and wood. This makes it a popular choice for creating complex parts and components in various industries. Laser cutting also finds applications in jewelry making and model making, where the ability to cut intricate and delicate designs is crucial.

With its precision and versatility, laser cutting has revolutionized the way complex patterns and designs are achieved in manufacturing and crafting.

Applications in Jewelry Making and Model Making

With its precise and intricate cuts, laser cutting has transformed the world of jewelry making and model making. This technology offers endless possibilities in creating stunning and detailed pieces in both industries. In fashion design, laser cutting allows for the creation of intricate patterns on fabrics and leather, adding a unique and stylish touch to garments and accessories. In industrial manufacturing, laser cutting is used to create precise and complex models, prototypes, and molds. It enables manufacturers to produce intricate designs with high accuracy and efficiency. To give you a better idea of the applications of laser cutting in jewelry making and model making, take a look at the table below:

| Applications in Jewelry Making | Applications in Model Making |

|---|---|

| Intricate metal cutouts | Complex architectural models |

| Engraving on gemstones | Detailed miniature figures |

| Customized pendants and earrings | Prototyping and mold making |

Now, let’s explore the next section about ‘interlocking design’ and discover how it enhances the versatility of laser cutting.

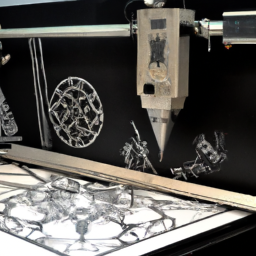

Interlocking Design

One effective technique for laser cutting thick materials is to incorporate an interlocking design. This design not only adds strength and stability but also creates an eye-catching visual appeal. By utilizing an interlocking design, you can achieve design flexibility, allowing for intricate patterns and shapes that would be difficult to achieve with other cutting methods.

Furthermore, this design technique ensures material compatibility. The interlocking pieces fit together seamlessly, reducing the risk of breakage or damage. Additionally, the interlocking design adds an element of sophistication to the final product, elevating its aesthetic value.

This technique sets the stage for the subsequent section about ‘perforated design,’ which further enhances the design possibilities for laser cutting thick materials.

Perforated Design

Enhance your laser-cut creations with a captivating perforated design that adds a unique and stylish touch to your projects.

Perforated designs have various applications in industrial manufacturing, making them a versatile choice for cutting thick materials. One of the main advantages of using a perforated design is its ability to enhance ventilation in these materials.

By incorporating small holes or patterns into the design, air can flow more freely, reducing the risk of heat build-up or damage. This is especially beneficial when working with materials that are prone to overheating or require adequate airflow for optimal performance.

Whether you’re creating intricate decorative pieces or functional components, a perforated design can add both aesthetic appeal and practical functionality to your laser-cut projects.

Frequently Asked Questions

What are the advantages of using laser cutting for thick materials compared to other cutting methods?

So you’re wondering why laser cutting is so great for cutting thick materials, huh? Well, let me tell you, there are quite a few advantages to using laser cutting over other methods.

Firstly, laser cutting is incredibly precise, making those thick cuts with absolute accuracy.

Secondly, it’s quick and efficient, saving you time and money.

And let’s not forget how clean and smooth the cuts are – no jagged edges here!

Laser cutting truly reigns supreme when it comes to thick materials.

Can laser cutting be used for materials other than metal?

Yes, laser cutting can be used for materials other than metal. Laser cutting has various applications in the fashion industry, where it’s commonly used to create intricate designs on fabrics and leather.

Additionally, laser cutting is effective for cutting acrylic and plastic materials, providing precise and clean cuts. Its versatility makes it a popular choice for many industries, offering a wide range of possibilities for creating unique and detailed designs.

Is it possible to achieve intricate and detailed designs with laser cutting on thick materials?

You might be surprised to learn that achieving intricate designs with laser cutting on thick materials isn’t as easy as it seems. While laser cutting is a versatile technique, it does have its limitations when it comes to thick materials. The laser’s power and intensity can be hindered by the thickness, making it challenging to achieve intricate details. However, there are certain techniques and adjustments that can be made to enhance the precision and intricacy of the designs.

What factors should be considered when choosing between different design options for laser cutting thick materials?

When choosing between different design options for laser cutting thick materials, there are several design considerations and factors to keep in mind.

First and foremost, the material thickness is crucial. You need to ensure that the design is suitable for the specific thickness of the material you’re working with.

Other factors include the complexity of the design, the desired level of detail, and the overall strength and durability of the final product.

Are there any limitations or challenges when using laser cutting for thick materials?

Are you aware of the limitations and challenges that come with using laser cutting for thick materials?

Cutting through dense materials can pose difficulties due to the increased power and precision required. Limitations may include slower cutting speeds and the need for multiple passes to achieve the desired depth.

Challenges often arise when dealing with heat buildup and potential warping of the material. It’s important to consider these factors when choosing laser cutting for thicker materials.

Conclusion

So there you have it, the top 5 designs for laser cutting thick materials. Whether you’re looking for a straight line design, a curved design, a lattice design, a geometric design, or an interlocking design, there’s something here for everyone.

And don’t worry about the material being too thick, because with laser cutting technology, it can handle it with ease. So go ahead, get creative, and let your imagination run wild. You’ll be amazed at what you can create!

Plus, it’s a fun and exciting way to bring your ideas to life.