Are you ready to embark on a journey into the fascinating world of 3D laser cutting? Prepare to be amazed as we delve into the ultimate guide to 3D laser cutting for beginners.

In this comprehensive article, we will take you through the basics, explore the applications, and equip you with the essential techniques and tips for successful 3D laser cutting.

With our step-by-step instructions and detailed explanations, you will gain a solid understanding of this cutting-edge technology. Whether you are a hobbyist, a DIY enthusiast, or a professional looking to expand your skills, this guide has got you covered.

But it doesn’t stop there. Safety precautions and maintenance tips are also included to ensure a safe and efficient working environment.

Plus, we will even show you how to further enhance your skills and knowledge in 3D laser cutting.

So, get ready to unleash your creativity and master the art of 3D laser cutting. Let’s dive in and unlock the endless possibilities that await you!

Key Takeaways

- 3D laser cutting offers numerous advantages and is used in various industries such as fashion and medicine.

- When choosing a 3D laser cutting machine, factors to consider include precision, material compatibility, and budget.

- Cost-effective materials and machine options can help in managing the budget for 3D laser cutting projects.

- Proper alignment, laser power and speed adjustment, and troubleshooting techniques are essential for successful 3D laser cutting.

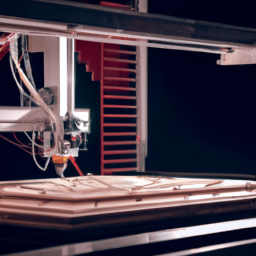

Understanding the Basics of 3D Laser Cutting

Before diving into the intricacies of 3D laser cutting, it’s crucial to grasp the fundamental concepts that underpin this innovative technology.

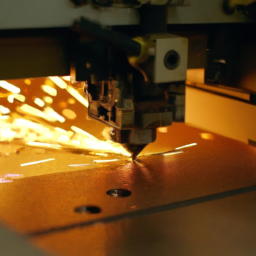

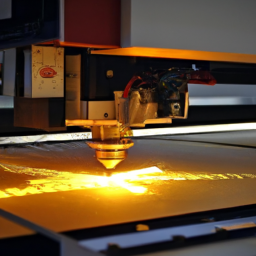

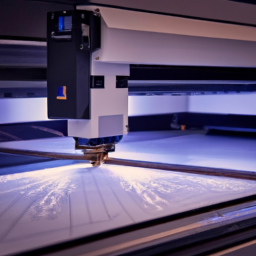

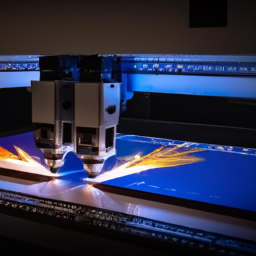

3D laser cutting offers numerous advantages over traditional cutting methods. It allows for intricate and precise cuts, reducing the need for manual labor and minimizing material waste. This technology is especially useful when working with common materials used in 3D laser cutting, such as metals, plastics, and wood.

The laser beam used in this process is directed by computer-aided design (CAD) software, ensuring accuracy and consistency in the final product. By harnessing the power of a focused laser beam, 3D laser cutting offers unparalleled precision and efficiency.

Now, let’s explore the applications of 3D laser cutting in various industries, showcasing its versatility and potential.

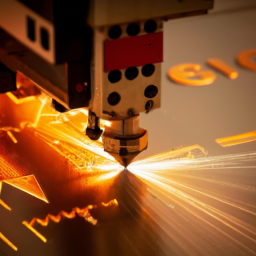

Exploring the Applications of 3D Laser Cutting

Let’s dive into the exciting world of 3D laser cutting and explore its wide range of applications!

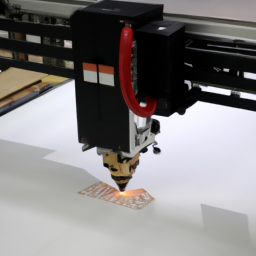

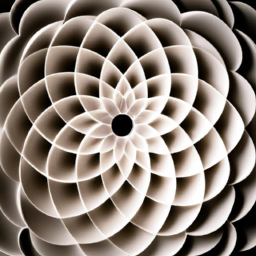

In the fashion industry, 3D laser cutting has revolutionized the way garments are designed and produced. It allows for intricate and precise cuts on various fabrics, creating unique patterns and textures that were once impossible to achieve. This technology has opened up endless possibilities for designers to push the boundaries of creativity and craftsmanship.

In the medical field, 3D laser cutting plays a crucial role in the manufacturing of medical devices and implants. It enables the production of intricate and customized designs, ensuring a perfect fit for patients. This precision cutting technique has significantly improved the quality and effectiveness of medical treatments.

Now that we have explored the applications of 3D laser cutting, let’s transition into the subsequent section about choosing the right 3D laser cutting machine.

Choosing the Right 3D Laser Cutting Machine

When selecting a 3D laser cutting machine, there are several factors to consider. You need to take into account your budget, the available features, and the technologies offered by different machines.

Budget considerations are crucial as they’ll determine which machine you can afford and the level of functionality you can expect. Additionally, you should thoroughly evaluate the available features and technologies to ensure they align with your specific needs and requirements.

Factors to Consider When Selecting a Machine

One important factor to consider when choosing a machine is the level of precision it offers. The machine capabilities play a crucial role in determining the quality of the final product. Look for a machine that can achieve high levels of accuracy and detail in its cuts.

Additionally, consider the material compatibility of the machine. Different materials may require specific laser settings or additional features to ensure optimal results. Ensure that the machine you select can handle the specific materials you plan to work with.

Once you’ve evaluated the machine’s precision and material compatibility, you can then move on to considering budget considerations.

Budget Considerations

Balancing the budget while buying a machine for laser cutting can be a bit baffling, but it’s crucial to consider cost-effectiveness and cutting-edge capabilities. When it comes to laser cutting materials, there are cost-effective options available that can help you stay within your budget.

Here are two sub-lists to consider:

-

Laser cutting materials:

- Acrylic: A popular choice due to its affordability and versatility.

- Plywood: Offers a cost-effective option for projects that don’t require high precision.

- Cardboard: An inexpensive material suitable for prototyping and temporary displays.

-

Cost-effective options:

- CO2 laser machines: These machines are known for their affordability and ability to cut a wide range of materials.

- Fiber laser machines: While they may have a higher initial cost, they offer lower operating costs and higher cutting speeds, making them cost-effective in the long run.

Considering these factors will help you make an informed decision within your budget.

Moving forward, let’s explore the available features and technologies that can enhance your laser cutting experience.

Available Features and Technologies

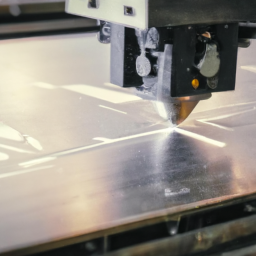

Now that you’ve considered the budget implications of 3D laser cutting, let’s delve into the available features and technologies that can enhance your cutting capabilities.

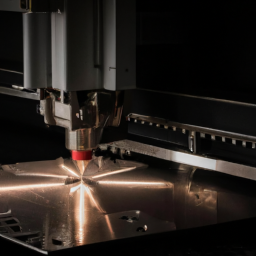

With advancements in the field, 3D laser cutting machines offer a range of advanced capabilities that can cater to your specific needs. These machines are equipped with emerging technologies that allow for precise and intricate cuts. Some of these technologies include high-power lasers, automatic material handling, and real-time monitoring systems.

The high-power lasers enable faster cutting speeds, while the automatic material handling systems ensure efficient workflow. Additionally, real-time monitoring systems provide feedback and adjustments to ensure accurate and consistent cuts.

By leveraging these advanced features and technologies, you can achieve superior results in your 3D laser cutting projects.

Now, let’s move on to the essential techniques and tips for successful 3D laser cutting, where you’ll learn how to optimize your cutting process for optimal outcomes.

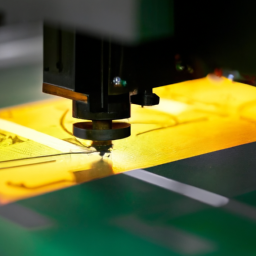

Essential Techniques and Tips for Successful 3D Laser Cutting

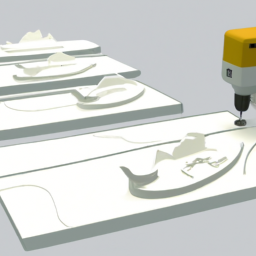

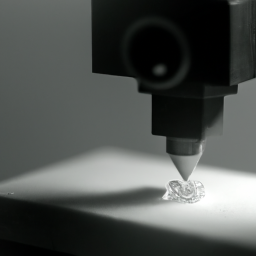

Mastering the art of 3D laser cutting is like unleashing a sculptor’s chisel, allowing precise and intricate designs to come to life. To achieve the utmost precision, there are several techniques you should employ.

Firstly, ensure that your material is properly aligned and securely fixed to avoid any unwanted movement during the cutting process. Additionally, adjusting the laser power and speed settings can greatly impact the quality of the cut. Troubleshooting common issues, such as excessive burning or incomplete cuts, requires careful observation and adjustment of the focal length and nozzle distance.

By implementing these techniques for precision and effectively troubleshooting, you can create flawless 3D laser-cut designs.

Moving on to the next section about safety precautions and maintenance for 3D laser cutting, it is imperative to prioritize the well-being of both the operator and the machine.

Safety Precautions and Maintenance for 3D Laser Cutting

To ensure your safety and maintain the longevity of your 3D laser cutting machine, it’s crucial that you follow proper safety precautions and perform regular maintenance tasks. Here are some maintenance tips and safety guidelines to help you keep your machine in optimal condition:

-

Clean the lens regularly to remove any dust or debris that may affect the quality of the laser beam.

-

Check and replace the coolant regularly to prevent overheating and ensure efficient operation.

-

Lubricate the moving parts, such as the rails and bearings, to reduce friction and ensure smooth movement.

By following these maintenance tips and safety guidelines, you can prevent accidents and prolong the lifespan of your 3D laser cutting machine.

Now, let’s move on to the next section to expand your skills and knowledge in 3D laser cutting.

Expanding Your Skills and Knowledge in 3D Laser Cutting

Enhance your expertise and broaden your understanding in 3D laser cutting by expanding your skills and knowledge. To truly excel in this field, it’s crucial to master advanced techniques that can take your creations to the next level.

One advanced technique is the ability to manipulate the laser power and speed settings to achieve different effects and levels of precision. Experimenting with these settings can lead to stunning results and allow you to push the boundaries of what’s possible with 3D laser cutting.

Additionally, being able to troubleshoot common issues is essential for a smooth workflow. Understanding how to identify and resolve problems such as material warping, inconsistent cutting depth, or misalignment will save you time and frustration.

Continuously expanding your skills and knowledge in 3D laser cutting will ensure your success in this exciting field.

Frequently Asked Questions

How much does a 3D laser cutting machine cost?

The cost of a 3D laser cutting machine varies depending on several factors. On average, a basic 3D laser cutting machine can cost around $50,000 to $100,000. However, more advanced models with higher precision and additional features can cost over $500,000.

Despite the high initial investment, 3D laser cutting machines offer numerous advantages, such as high precision, versatility, and fast cutting speeds.

Disadvantages include the need for skilled operators and regular maintenance.

What materials can be used with a 3D laser cutting machine?

When using a 3D laser cutting machine, it’s important to consider different techniques for optimizing material usage. One interesting statistic is that utilizing nesting software can increase material utilization by up to 15%. This software helps arrange parts more efficiently, reducing waste and saving costs.

Additionally, exploring the benefits of using unconventional materials with a 3D laser cutting machine can open up new possibilities. By experimenting with materials like wood, fabric, or even food products, you can create unique and innovative designs.

Is it possible to create intricate designs with a 3D laser cutting machine?

Yes, it’s possible to create intricate designs with a 3D laser cutting machine. The benefits of using this machine are numerous.

The 3D laser cutting machine can produce detailed and complex designs with its high precision and accuracy. It can cut through various materials, including metals and plastics, allowing for a wide range of creative possibilities.

Additionally, the machine’s speed and efficiency make it a valuable tool for achieving intricate designs in a timely manner.

Can a 3D laser cutting machine be used for both small and large projects?

Yes, a 3D laser cutting machine can be used for both small and large projects. The capabilities of a 3D laser cutting machine make it suitable for a wide range of project sizes. For small-scale projects, the machine offers the advantage of precision and intricate detailing.

On the other hand, for large-scale projects, considerations such as material size and machine capacity need to be taken into account. To optimize efficiency and accuracy, it’s important to adjust settings and parameters based on the specific project size and requirements.

Are there any limitations or restrictions to consider when using a 3D laser cutting machine?

When using a 3D laser cutting machine, there are some limitations to consider. The size of the machine’s working area may restrict the size of the projects you can undertake.

Additionally, the thickness of the material being cut can affect the machine’s performance.

Safety precautions are crucial when operating a 3D laser cutting machine. It’s important to wear protective eyewear and gloves, and to ensure a well-ventilated environment to prevent exposure to fumes.

Conclusion

In conclusion, dear reader, you’ve embarked on a journey through the vast realm of 3D laser cutting. Like an artist wielding a brush, you’ve learned the basics, explored the applications, and chosen the perfect machine.

With essential techniques and tips at your disposal, you now possess the power to create intricate masterpieces. But remember, dear adventurer, safety and maintenance are your faithful companions on this path.

As you continue to expand your skills and knowledge, may you unlock the limitless possibilities of 3D laser cutting.