So, you’ve decided to dip your toes into the world of subtractive laser cutting? Well, my friend, you’ve come to the right place. Prepare yourself for a journey that will take you from novice to expert in no time.

This ultimate guide is here to hold your hand and show you the ropes of this mesmerizing technique.

But let’s be real for a moment. Subtractive laser cutting may seem daunting at first, with its intricate machinery and precise measurements. It’s like trying to tame a wild beast, isn’t it? Well, fear not, because we’re here to help you conquer it.

In this guide, we’ll break down the basics of subtractive laser cutting, explore its various applications, and delve into the advantages it offers.

We’ll give you a step-by-step walkthrough, ensuring you understand each stage of the process.

And of course, we won’t forget about safety precautions and maintenance tips, because your well-being matters.

So, are you ready to unlock the secrets of subtractive laser cutting? Let’s dive in and unleash your creativity like never before.

Key Takeaways

- Subtractive laser cutting is a complex process but can be broken down into basic steps.

- It has various applications, including creating intricate designs, customizing gifts, and small-scale manufacturing.

- The advantages of subtractive laser cutting include high precision, versatility, and the elimination of tooling.

- To ensure optimal performance, regular maintenance, safety precautions, and troubleshooting common issues are necessary.

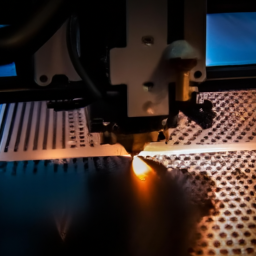

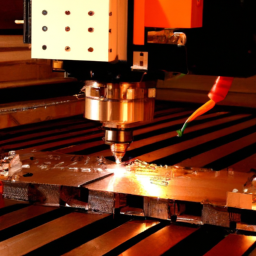

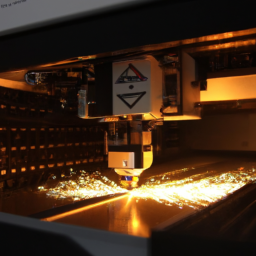

Understanding the Basics of Subtractive Laser Cutting

Now that you’ve grasped the fundamental concepts, it’s time to delve deeper into the intricacies of subtractive laser cutting. To maximize efficiency in this process, it’s important to understand the basics.

One key aspect is troubleshooting common issues that may arise during subtractive laser cutting. These issues could include uneven cuts, material burning, or misalignment. By familiarizing yourself with these problems and their solutions, you can ensure a smoother cutting process and achieve more precise results.

Additionally, it’s crucial to properly maintain and clean the laser cutting machine regularly, as this can prevent potential issues and help prolong its lifespan.

With a solid understanding of the basics and troubleshooting techniques, you will be well-prepared to explore the vast applications of subtractive laser cutting, from crafting intricate designs to industrial manufacturing processes.

Applications of Subtractive Laser Cutting

In this discussion, you’ll explore the various applications of subtractive laser cutting. You’ll discover how it can be used to create intricate designs and patterns, allowing you to bring your artistic visions to life.

Additionally, you’ll learn how this technology can be utilized to customize personalized gifts and accessories, adding a unique touch to your creations.

Lastly, you’ll delve into how subtractive laser cutting is valuable for prototyping and small-scale manufacturing. It enables you to quickly and accurately produce prototypes and small batches of products.

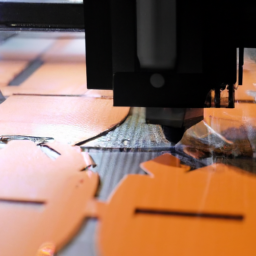

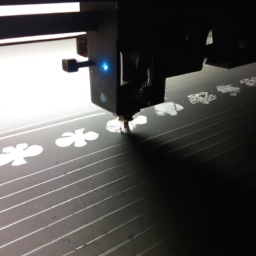

Creating Intricate Designs and Patterns

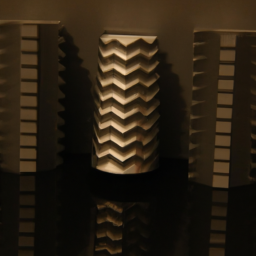

Discover the joy of crafting detailed and intricate designs with the power of subtractive laser cutting. With advanced laser techniques, you can easily create stunning patterns and designs that were once only possible through hours of tedious handwork.

Whether you want to make delicate lace-like cutouts or intricate geometric shapes, subtractive laser cutting allows you to achieve precise and flawless results. Plus, troubleshooting common issues becomes a breeze with the help of online resources and communities of laser cutting enthusiasts.

So, dive into the world of subtractive laser cutting and explore the endless possibilities of creating intricate designs that’ll leave everyone in awe.

Now, let’s move on to the next section and learn how to customize personalized gifts and accessories without any hassle.

Customizing Personalized Gifts and Accessories

Unleash your creativity and effortlessly transform ordinary gifts and accessories into one-of-a-kind masterpieces with the magic of personalized laser customization. Whether it’s a piece of personalized jewelry or laser-cut home decor, the possibilities are endless.

With subtractive laser cutting, you can add intricate details, names, or special messages to make your gifts truly unique. Imagine surprising your loved ones with a custom-engraved necklace or a beautifully etched picture frame. Not only will it show how much you care, but it will also leave a lasting impression.

And it’s not just limited to gifts; you can also customize accessories like phone cases, keychains, or even leather wallets. The laser precision ensures high-quality results that are sure to impress.

So, why settle for ordinary when you can create extraordinary? Now, let’s dive into the world of prototyping and small-scale manufacturing.

Prototyping and Small-scale Manufacturing

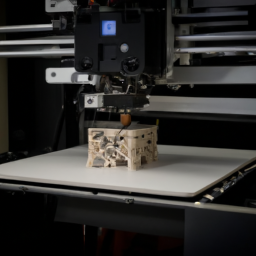

Explore the world of prototyping and small-scale manufacturing and witness the remarkable potential of personalized laser customization.

With subtractive laser cutting, you can turn your ideas into reality and create prototypes for your small business opportunities. The process allows you to quickly iterate and refine your designs, saving you time and money compared to traditional manufacturing methods.

Material selection is crucial in this process, as different materials may require different laser settings and produce varying results. From wood and acrylic to leather and metal, the possibilities are endless. By experimenting with different materials, you can explore unique product possibilities and tailor your offerings to meet the demands of your target market.

Discover the advantages of subtractive laser cutting and unlock your creativity in the next section.

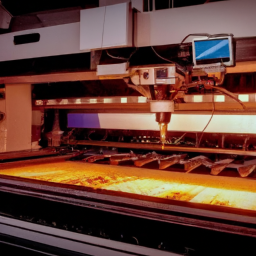

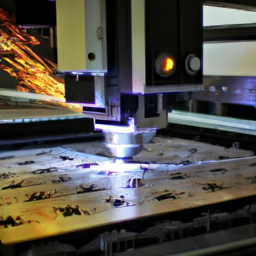

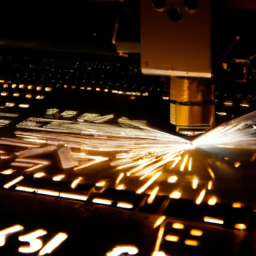

Advantages of Subtractive Laser Cutting

One of the perks of subtractive laser cutting is that it allows you to have your cake and eat it too – you can create intricate designs with precision and speed. Unlike other cutting methods, subtractive laser cutting offers several advantages.

First, it allows for high precision, as the laser beam can be controlled to cut through materials with extreme accuracy, resulting in intricate and detailed designs.

Second, it is a fast process, allowing for quick production of prototypes or small-scale manufacturing.

Additionally, subtractive laser cutting is versatile and can be used on a wide range of materials, including wood, acrylic, and metal.

This method also eliminates the need for tooling, reducing costs and setup time.

With these advantages in mind, let’s move on to the step-by-step guide to subtractive laser cutting.

Step-by-Step Guide to Subtractive Laser Cutting

To get started with subtractive laser cutting, you need to prepare your design file first. This involves converting your design into a compatible file format and making sure the dimensions are accurate.

Next, you’ll set up the laser cutting machine by adjusting the focus, positioning the material, and securing it in place. Once everything is in place, you’ll test and adjust the cutting parameters to ensure the desired results.

Preparing Your Design File

Before diving into the process of subtractive laser cutting, it’s crucial to understand the importance of preparing your design file to ensure precision and efficiency. When it comes to designing considerations, think about the overall size and shape of your design, as well as any intricate details or delicate features that may need special attention. Additionally, consider the file formats and compatibility, as different laser cutting machines may require specific file types.

In terms of emotional response, imagine the satisfaction of seeing your meticulously designed creation come to life with laser precision. Picture the excitement of holding your finished product in your hands, knowing that it was made possible through careful file preparation. On the other hand, the frustration of encountering compatibility issues or having to redo a design due to oversight can be disheartening.

Now that you understand the importance of preparing your design file, let’s move on to setting up the laser cutting machine and bringing your vision to reality.

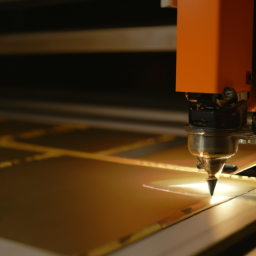

Setting Up the Laser Cutting Machine

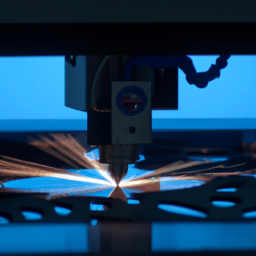

Get ready to bring your design to life by setting up the laser cutting machine and watching your vision come to reality.

Before you start, make sure to troubleshoot common issues that may arise during the setup process. Check the laser power, the lens cleanliness, and the alignment of the material.

Once everything is in order, it’s time to optimize cutting speed. Adjust the speed settings according to the material you’re working with, as different materials require different cutting speeds for optimal results. Take into consideration the thickness and density of the material to achieve clean and precise cuts.

With the laser cutting machine set up and the cutting speed optimized, you’re now ready to move on to the next step of testing and adjusting the cutting parameters to ensure the best possible outcome for your project.

Testing and Adjusting the Cutting Parameters

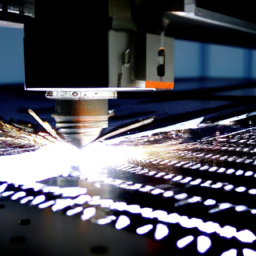

Now it’s time for you to fine-tune the cutting parameters and experiment with different settings to achieve the desired outcome for your project.

Testing accuracy is crucial in ensuring that your laser cutting machine is functioning optimally. Start by adjusting the speed setting to find the right balance between accuracy and efficiency. Slow down the speed if you notice any inaccuracies in the cuts, and increase it if the cuts are too slow.

Additionally, you can adjust the power and frequency settings to further optimize the cutting process. Keep testing and making small adjustments until you achieve the desired results.

Once you’ve mastered the cutting parameters, it’s important to move on to the next section about safety precautions and maintenance tips for subtractive laser cutting. Maintaining your machine’s performance is crucial for its longevity and safety.

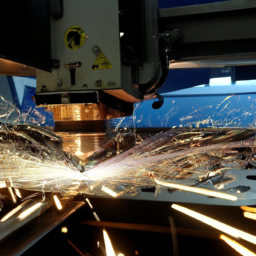

Safety Precautions and Maintenance Tips for Subtractive Laser Cutting

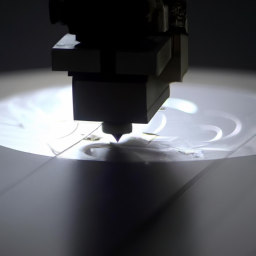

Ensure your safety while operating a laser cutter by wearing the necessary laser cutting safety equipment, such as safety glasses and gloves, to protect your eyes and hands from potential harm.

Additionally, it is crucial to regularly maintain the laser cutting machine to prevent any potential accidents. Create a maintenance checklist for your laser cutting machine, including tasks such as cleaning the lenses, checking the alignment, and ensuring proper ventilation.

Regularly inspect and replace any worn-out parts to maintain optimal performance.

By following these safety precautions and maintaining your laser cutter, you can minimize the risk of accidents and ensure its longevity.

With your safety in mind, let’s now transition into exploring advanced techniques and tips for subtractive laser cutting.

Exploring Advanced Techniques and Tips for Subtractive Laser Cutting

Master the art of subtractive laser cutting with these advanced techniques and tips, allowing you to unleash your creativity and precision like a seasoned pro. Here are four advanced laser cutting techniques to take your skills to the next level:

-

Multiple Passes: Achieve deeper cuts and smoother edges by running the laser cutter over the same area multiple times. This technique is especially effective when working with thicker materials.

-

Variable Speed: Experiment with adjusting the cutting speed during the process to achieve different effects. Slower speeds can result in cleaner cuts, while faster speeds can produce unique textures and patterns.

-

Air Assist: Improve the quality of your cuts by using an air assist system. This helps to remove debris and prevents the material from overheating, resulting in cleaner and more precise cuts.

-

Troubleshooting: Familiarize yourself with common issues in subtractive laser cutting, such as excessive smoke or charring. Troubleshoot these problems by adjusting the power and speed settings, as well as ensuring proper ventilation.

By employing these advanced techniques and troubleshooting common issues, you’ll be able to push the boundaries of subtractive laser cutting and achieve remarkable results.

Frequently Asked Questions

Can I use a laser cutter to cut materials other than wood and metal?

Yes, you can definitely use a laser cutter to cut materials other than wood and metal. Laser cutting is a versatile technique that can be used on various materials, including fabrics and acrylics. It provides precise and clean cuts, making it an ideal choice for intricate designs and patterns.

So, whether you’re working on a DIY project or creating personalized items, a laser cutter can help you achieve professional results on fabrics and acrylics.

What is the average cost of a laser cutting machine?

When considering the average cost of a laser cutting machine, it’s important to evaluate the advantages it offers over traditional cutting methods.

Laser cutting provides precise and clean cuts, minimizing material waste.

Factors to consider when choosing a machine include the power and speed capabilities, the type of materials it can handle, and the level of automation desired.

Remember, investing in a high-quality laser cutting machine can lead to increased productivity and cost savings in the long run.

How can I optimize the speed and accuracy of my laser cutting process?

To maximize efficiency and improve cutting quality in your laser cutting process, there’s one interesting statistic you should know. According to industry research, optimizing the speed of your laser cutter can increase productivity by up to 30%.

To achieve this, consider adjusting the cutting parameters, such as power and speed settings, and using high-quality materials. Additionally, regularly maintaining and calibrating your machine will ensure accuracy and precision in your cuts.

Are there any environmental considerations to keep in mind when using a laser cutter?

When using a laser cutter, there are important environmental considerations to keep in mind. The environmental impact of laser cutting can be significant, as it produces fumes and emissions that can be harmful. To minimize these effects, it’s crucial to take safety precautions, such as using proper ventilation systems and wearing protective gear.

Additionally, it’s important to dispose of waste materials responsibly and follow local regulations for proper disposal methods.

Can laser cutting machines be used for engraving or marking materials?

Laser cutting machines aren’t just limited to cutting materials; they can also be used for engraving or marking. In fact, laser engraving is becoming increasingly popular due to its precision and versatility.

Compared to traditional engraving methods, laser cutting offers several advantages. For one, it allows for intricate designs and fine details that would be difficult to achieve with other methods. Additionally, laser marking is faster and more efficient, making it a preferred choice for many industries.

Conclusion

So, now you’ve got a comprehensive understanding of subtractive laser cutting. You’ve learned about its basics, applications, and advantages.

With the step-by-step guide, you’re ready to dive into this fascinating world of precision cutting. Remember to prioritize safety precautions and maintenance to ensure a smooth operation.

And as you explore advanced techniques and tips, you’ll discover that subtractive laser cutting is like a sculptor’s chisel, shaping materials with precision and artistry.

So go ahead, unleash your creativity, and let the laser do the magic!