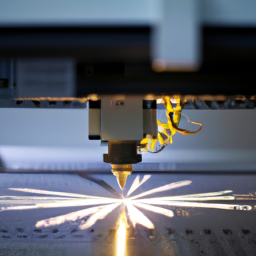

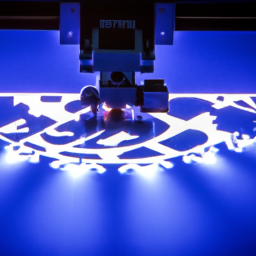

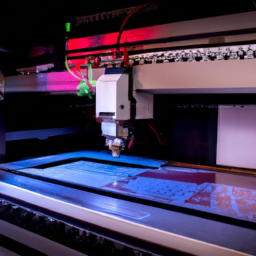

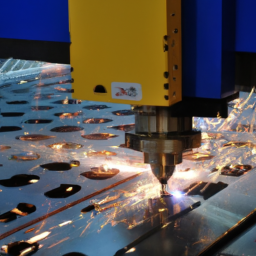

Did you know that nearly 80% of issues with fiber laser cutters can be easily resolved with proper troubleshooting?

Whether you’re a beginner or an experienced user, understanding how to troubleshoot your fiber laser cutter is essential for maintaining optimal performance and minimizing downtime.

In this ultimate guide, we will walk you through the most common problems you may encounter and provide detailed solutions to get you back on track.

From power fluctuations and focus alignment to cutting quality and cooling system issues, we’ve got you covered.

Additionally, we’ll address software and controller problems, as well as offer maintenance and cleaning tips to keep your machine running smoothly.

By the end of this guide, you’ll have the knowledge and confidence to tackle any issues that arise, ensuring maximum productivity and efficiency with your fiber laser cutter.

Let’s dive in and become a troubleshooting pro!

Key Takeaways

- Troubleshooting is essential for maintaining optimal performance and minimizing downtime.

- Power fluctuations can disrupt the laser’s stability and cause inconsistent cutting results or failure.

- Proper focus alignment is crucial for sharp and focused cutting.

- Regular maintenance and cleaning is crucial to prolong the lifespan of a fiber laser cutter and minimize the need for troubleshooting techniques.

Power Fluctuations

Power fluctuations can cause significant damage to your fiber laser cutter, so it’s important to address them promptly.

To ensure laser safety and prevent any potential issues, it is crucial to understand how power fluctuations can affect your equipment. When power fluctuations occur, they can disrupt the laser’s stability, leading to inconsistent cutting results or even complete failure.

To troubleshoot power fluctuations, start by checking the power supply and connections to ensure they’re secure and functioning correctly. It’s also important to verify that the power input matches the laser cutter’s specifications.

Additionally, consider installing a voltage stabilizer or surge protector to protect against sudden voltage spikes or drops.

Following these troubleshooting techniques will help you maintain a stable power supply and prevent damage to your fiber laser cutter.

Focus Alignment

To get your focus alignment right, make sure you’ve got your ‘eye on the prize’ and follow these steps:

-

Clean the lens: Start by checking for any lens contamination. Even the tiniest speck of dust can affect the focal point. Use a clean, lint-free cloth and a gentle cleaning solution to wipe the lens clean.

-

Check the beam path: Make sure the beam path is clear and unobstructed. Remove any debris or materials that may be blocking the beam.

-

Adjust the height: Use the height adjustment mechanism to position the material at the correct distance from the lens. This is crucial for achieving a sharp and focused beam.

-

Test and fine-tune: Run a test cut on a sample piece of material and inspect the result. If the cut is not clean or the focal point is off, make small adjustments to the focus until the desired result is achieved.

Remember, proper focus alignment is essential for getting the best cutting performance out of your fiber laser cutter.

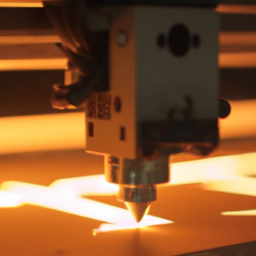

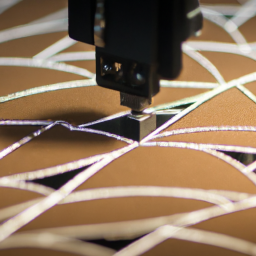

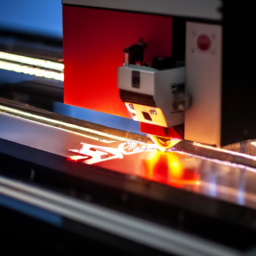

Cutting Quality

When troubleshooting the cutting quality of your fiber laser cutter, there are three key points to consider.

First, check the material thickness and compatibility to ensure it’s within the machine’s capabilities.

Next, adjust the cutting parameters to optimize the laser’s performance for the specific material being cut.

Lastly, inspect and clean or replace any worn or damaged cutting head components that may be affecting the quality of the cuts.

Check Material Thickness and Compatibility

First and foremost, it’s essential to ensure that the material you’re using is the right thickness and compatible with your fiber laser cutter. Material compatibility is crucial because using the wrong type of material can result in poor cutting quality and potential damage to the machine. Additionally, the thickness of the material plays a significant role in determining the optimal cutting settings. To help you determine the correct material thickness and compatibility, refer to the following table:

| Material Type | Recommended Thickness Range | Compatibility |

|---|---|---|

| Steel | 0.5mm – 25mm | Compatible |

| Aluminum | 0.5mm – 10mm | Compatible |

| Acrylic | 1mm – 20mm | Compatible |

By measuring the thickness of your material and cross-referencing it with the recommended range in the table, you can ensure that you achieve the best cutting results and prevent any potential issues.

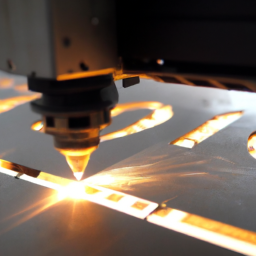

Adjust Cutting Parameters

Adjusting the cutting parameters allows for precise control over the laser’s intensity and speed, resulting in accurate and clean cuts. To improve efficiency and optimize performance, follow these steps:

-

Adjust the laser power: Increase or decrease the power output to match the material being cut. Higher power settings are suitable for thicker or denser materials, while lower power settings work best for thinner or more delicate materials.

-

Fine-tune the cutting speed: Adjust the speed at which the laser moves across the material. Slower speeds provide more time for the laser to penetrate and cut through thicker materials, while faster speeds work well for thinner materials.

-

Set the focus distance: Ensure the laser beam is focused at the right distance from the material’s surface. This helps maintain a concentrated and precise cutting beam.

-

Optimize the assist gas flow: Adjust the flow rate of the assist gas, such as oxygen or nitrogen, to enhance the cutting process. The assist gas helps blow away molten material and ensure clean cuts.

By carefully adjusting these cutting parameters, you can improve the efficiency and optimize the performance of your fiber laser cutter, resulting in high-quality and accurate cuts.

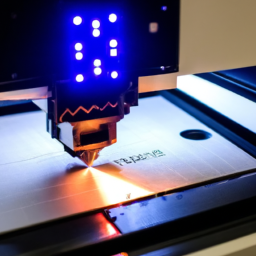

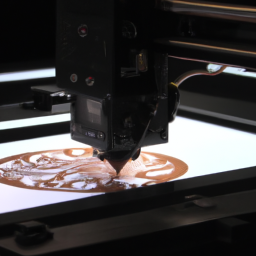

Clean or Replace Cutting Head Components

To ensure optimal performance, it’s important to regularly clean or replace the components of the cutting head. Cleaning techniques are essential for maintaining the efficiency of your fiber laser cutter.

Start by disconnecting the power and removing the cutting head from the machine. Use a soft brush or compressed air to remove any dust or debris from the lens, mirror, and nozzle. Be careful not to scratch the surfaces. For stubborn dirt, you can use a mild cleaning solution and a lint-free cloth.

When replacing components, refer to the manufacturer’s guidelines to ensure proper installation. Troubleshooting techniques can also help identify when a component needs to be replaced. If you notice a decrease in cutting quality or inconsistent results, it may be time to clean or replace the cutting head components.

Cooling System Issues

One common issue with fiber laser cutters is when the cooling system isn’t pulling its weight, leaving you in hot water. Proper cooling system maintenance is crucial to ensure the efficient operation of your laser cutter. If you notice coolant leaks, it’s important to troubleshoot and address the issue promptly.

Here are a couple of things to consider:

-

Common causes of coolant leaks:

- Loose or damaged fittings: Inspect all connections and tighten any loose fittings. Replace damaged fittings as necessary.

- Cracked or worn hoses: Check for cracks or signs of wear on the hoses. Replace any damaged hoses to prevent leaks.

-

Troubleshooting coolant leaks:

- Inspect the coolant reservoir: Ensure that the reservoir isn’t overfilled or empty. Adjust the coolant level as needed.

- Check the pump: Verify that the pump is functioning properly and delivering coolant to the cutting head. Clean or replace the pump if necessary.

Regularly maintaining and troubleshooting your cooling system can help prevent issues and keep your fiber laser cutter running smoothly.

Software and Controller Problems

To ensure smooth operation of your fiber laser cutter, it’s important to address any software and controller problems that may arise.

Start by updating the software and firmware to the latest versions to benefit from any bug fixes or performance enhancements.

Additionally, check the connection cables and ports to ensure they’re securely connected and not damaged.

Lastly, test the controller settings and functions to verify that they’re working properly. Make any necessary adjustments for optimal performance.

Update Software and Firmware

Make sure you’re running the latest software and firmware on your fiber laser cutter to ensure optimal performance and avoid any potential issues. Keeping your software and firmware up to date is essential for troubleshooting software-related problems and taking advantage of the latest features and improvements. Here are some simple steps to update your software and firmware:

| Step | Description |

|---|---|

| 1 | Check the manufacturer’s website or contact customer support to find the latest software and firmware versions available for your laser cutter model. |

| 2 | Download the software and firmware files onto your computer. |

| 3 | Connect your computer to the laser cutter using a USB cable or other appropriate connection method. |

| 4 | Follow the manufacturer’s instructions to install the new software and firmware onto your laser cutter. |

By regularly updating your software and firmware, you can ensure that your fiber laser cutter operates smoothly and efficiently, minimizing potential software-related issues and maximizing productivity.

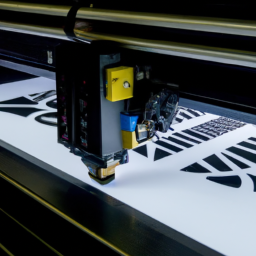

Check Connection Cables and Ports

Ensure that the connection cables and ports are properly checked and secured to maintain a seamless and efficient operation of your laser cutter. When troubleshooting your fiber laser cutter, it’s essential to examine the connection cables and ports to identify any potential issues.

Start by inspecting the cables for any visible damage or loose connections. Ensure that all cables are securely plugged into their respective ports, and there are no obstructions or bends that could affect the signal transmission.

Additionally, practice good cable management techniques, such as organizing and securing the cables away from moving parts, to prevent accidental disconnections or damage.

Regularly check the connections and cables to maintain a reliable and uninterrupted performance of your fiber laser cutter.

Test Controller Settings and Functions

Don’t overlook the importance of testing your controller settings and functions to optimize the performance of your laser cutter. Testing the controller speed is crucial to ensure that your fiber laser cutter operates at the desired pace. You can perform a speed test by setting the controller to different speeds and observing how accurately it executes the commands. This will help you identify any issues with the controller’s ability to maintain consistent speeds.

Additionally, testing the controller accuracy is essential for achieving precise cuts. You can assess the accuracy by running test cuts on various materials and measuring the deviation from the desired dimensions. This will allow you to make any necessary adjustments to ensure that your fiber laser cutter delivers accurate and reliable results.

Maintenance and Cleaning Tips

Though often overlooked, regular maintenance and cleaning of your fiber laser cutter is crucial for ensuring optimal performance and longevity. To help you keep your machine in top shape, here are some maintenance and cleaning tips:

- Clean the lens regularly using a lint-free cloth and isopropyl alcohol to remove any residue or debris that may affect the laser beam quality.

- Check and clean the filter regularly to prevent dust and particles from clogging the system and causing damage.

- Lubricate the moving parts of the machine according to the manufacturer’s instructions to ensure smooth operation.

- Inspect the cables and connections for any signs of wear or damage, and replace them if necessary.

- Keep a troubleshooting checklist handy to quickly identify and address any issues that may arise.

By following these maintenance and cleaning tips, you can prolong the lifespan of your fiber laser cutter and minimize the need for troubleshooting techniques.

Frequently Asked Questions

How can I determine if the power fluctuations in my fiber laser cutter are due to internal issues or external factors?

To determine if power fluctuations in your fiber laser cutter are due to internal issues or external factors, you need to follow a troubleshooting process.

Start by checking the power supply and connections for any loose or damaged components.

Next, monitor the power fluctuations during different operating conditions, such as varying loads or environmental changes.

If the fluctuations persist despite these checks, it may indicate internal issues like faulty components or circuitry.

Seek professional assistance to further diagnose and resolve the problem.

What are the common signs of misalignment in the focus of a fiber laser cutter and how can I fix it?

To identify signs of misalignment in the focus of your fiber laser cutter, look out for uneven cutting depth, decreased cutting speed, or a blurry or distorted laser beam.

To fix this issue, start by checking the alignment of the laser head and lens. Ensure that the lens is clean and properly positioned.

If misalignment persists, consult the manufacturer’s troubleshooting guide or contact customer support for further assistance.

Are there any specific factors that can affect the cutting quality of a fiber laser cutter, other than power fluctuations and focus alignment?

Imagine your fiber laser cutter as a delicate symphony orchestra. Just like an orchestra, a variety of factors can affect the cutting quality of your machine.

Factors such as improper material support, lens contamination, beam alignment, and nozzle condition can all impact the precision and consistency of your cuts.

Troubleshooting power fluctuations and ensuring proper focus alignment are essential, but don’t forget to address these other factors to achieve optimal cutting quality.

What are some common cooling system issues that can arise in a fiber laser cutter and how can I troubleshoot them?

To troubleshoot common cooling system issues in a fiber laser cutter, start by analyzing power fluctuations. Check the power source and make sure it’s stable.

Inspect the cooling system for any leaks, blockages, or insufficient coolant levels. Clean or replace the filters and make sure the coolant is properly circulating.

Verify that the cooling fans are functioning correctly and not obstructed. Regular maintenance and monitoring of the cooling system will help prevent potential issues and ensure optimal performance.

Are there any known software or controller problems that are commonly encountered with fiber laser cutters, and what are the recommended solutions for them?

Software glitches and controller malfunctions are common issues that can arise with fiber laser cutters. These problems can cause disruptions in the cutting process and hinder productivity. To address software glitches, ensure that you have the latest software updates and check for compatibility issues with your operating system.

For controller malfunctions, inspect the wiring connections and power supply. If necessary, contact the manufacturer or a technician for further assistance.

Conclusion

In the vast realm of laser cutting, troubleshooting your fiber laser cutter is an essential skill to master. You must navigate through power fluctuations, align the focus with precision, and ensure cutting quality remains impeccable. As you sail through the sea of cooling system issues and software glitches, remember to perform regular maintenance and cleaning rituals to keep your cutter in prime condition. Embrace the role of a troubleshooter, and let your laser cutter sail smoothly on the waves of productivity.