Are you ready to cut through the noise and make precise cuts that will leave you in awe? Well, hold on tight because we’re about to take you on a journey through the top 10 subtractive laser cutting machines for precision cutting.

These machines are the crème de la crème, the cream of the crop, the bees knees, if you will. Picture this: you’re standing in front of a sleek, state-of-the-art machine, with its laser beam ready to slice through any material with surgical precision.

Whether it’s the Fiber Laser Cutting Machine, CO2 Laser Cutting Machine, YAG Laser Cutting Machine, UV Laser Cutting Machine, Plasma Laser Cutting Machine, or Waterjet Cutting Machine, these cutting-edge devices will leave you astounded.

With their second-to-none accuracy, versatility, and efficiency, you’ll be able to bring your wildest ideas to life. So buckle up and get ready to discover the epitome of precision cutting!

Key Takeaways

- Fiber Laser Cutting Machine: Fast cutting speed, energy-efficient, versatile

- CO2 Laser Cutting Machine: Cuts wood, acrylic, fabric with precision, minimal heat-affected zones, high cutting speeds

- YAG Laser Cutting Machine: Versatile and accurate, cuts metals, ceramics, plastics, diamonds, cuts reflective materials

- UV Laser Cutting Machine: Perfect for delicate materials, minimal heat-affected zone, high precision and fine detail

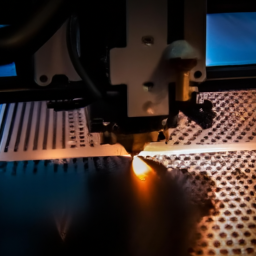

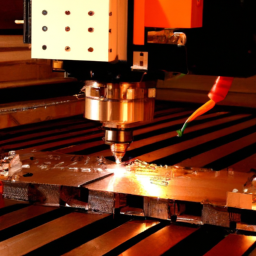

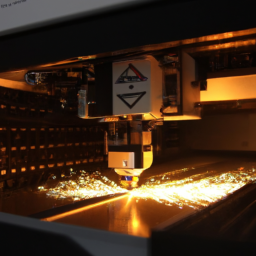

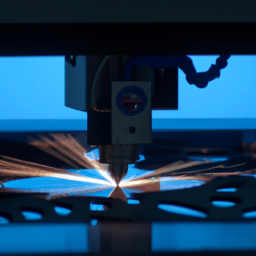

Fiber Laser Cutting Machine

The fiber laser cutting machine effortlessly slices through metal like a hot knife through butter, leaving behind clean and precise cuts. Compared to a CO2 laser, the fiber laser offers several advantages.

Firstly, it has a higher cutting speed, allowing for faster production times. Secondly, the fiber laser is more energy-efficient, resulting in reduced operating costs. Additionally, the fiber laser is capable of cutting a wide range of materials, including metals, plastics, and composites, making it a versatile option for various industries. Its narrow beam allows for intricate and detailed cuts, ensuring precision and accuracy.

Transitioning into the subsequent section about the CO2 laser cutting machine, it is important to note that while the fiber laser excels in certain areas, the CO2 laser has its own unique benefits and applications.

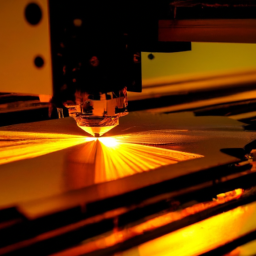

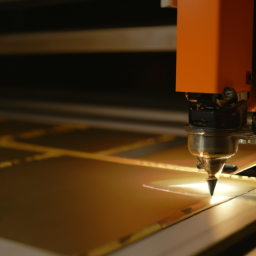

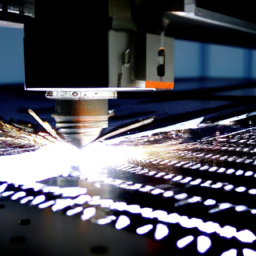

CO2 Laser Cutting Machine

Explore the CO2 laser cutting machine, an exceptional tool for achieving intricate and accurate cuts. This laser cutting technology utilizes a carbon dioxide gas mixture to generate a high-powered laser beam.

The advantages of using a CO2 laser cutting machine include its ability to cut through a wide range of materials such as wood, acrylic, and fabric with precision. Additionally, it produces minimal heat-affected zones, resulting in clean and smooth edges. Furthermore, the CO2 laser cutting machine offers high cutting speeds, making it ideal for large-scale production.

However, it also has some disadvantages, such as high maintenance costs and limitations when cutting reflective materials.

Transitioning into the subsequent section about the ‘yag laser cutting machine,’ let’s now delve into another remarkable subtractive laser cutting option.

YAG Laser Cutting Machine

Get ready to discover the incredible power of the YAG laser cutting machine, where precision meets the art of creating intricate designs. YAG laser cutting machines are widely used in various industries due to their versatility and accuracy. These machines have a wide range of applications, including cutting metals, ceramics, plastics, and even diamonds.

The YAG laser’s high-energy beam allows for precise and clean cuts, making it perfect for intricate designs and delicate materials. One of the advantages of YAG laser cutting is its ability to cut reflective materials like copper and brass without any issues. Additionally, the YAG laser offers a high level of control, allowing for complex shapes and patterns to be cut with ease.

Now, let’s move on to the next section about the UV laser cutting machine and explore its unique capabilities.

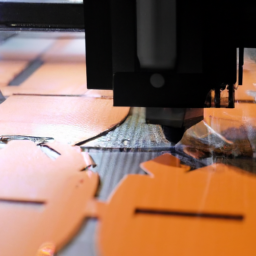

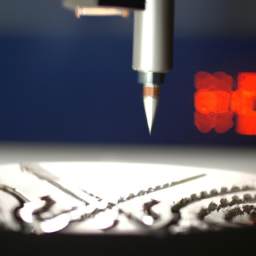

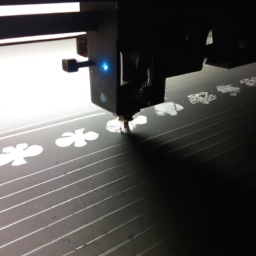

UV Laser Cutting Machine

If you’re looking for a laser cutting machine that’s perfect for delicate materials, then the UV Laser Cutting Machine is the one for you. It ensures that your materials won’t be damaged during the cutting process with its minimal heat-affected zone. Not only that, but it also offers high precision and fine detail, making it ideal for intricate designs and patterns.

Perfect for delicate materials

When you’re working with delicate materials, these laser cutting machines are the perfect choice for achieving precise cuts. They not only offer laser engraving capabilities but are also capable of cutting intricate designs with utmost accuracy. The laser technology used in these machines ensures that the delicate materials are not damaged or distorted during the cutting process.

With their high precision and fine-tuned settings, you can trust these machines to cut through even the most intricate designs without any issues. What sets these machines apart is their ability to create a minimal heat-affected zone during the cutting process. This means that your delicate materials won’t be subjected to excessive heat, ensuring their integrity and quality.

Minimal heat-affected zone

You’ll be amazed at how these laser cutting machines can effortlessly slice through materials without leaving a trace of heat damage, ensuring your delicate creations remain unscathed. With their advanced technology, these machines offer reduced thermal distortion, resulting in clean and precise cuts.

The minimal heat-affected zone means that even the most fragile materials, such as paper or fabric, can be flawlessly cut without any risk of burning or warping. Imagine the possibilities of creating intricate designs with utmost precision, knowing that every cut will be perfect.

But these machines don’t just stop at precision cutting; they also offer high precision and fine detail, allowing you to bring your imagination to life.

Transitioning into the next section, you’ll discover how these cutting-edge machines can take your projects to a whole new level.

Offers high precision and fine detail

Get ready to be blown away by the incredible precision and fine detail that these state-of-the-art machines offer. They allow you to create jaw-dropping designs with ease. The high precision advantages of these subtractive laser cutting machines ensure that every cut is made with utmost accuracy, resulting in clean and flawless edges. Whether you’re working on intricate patterns or delicate materials, these machines excel in delivering the finest details that’ll leave you amazed.

With their advanced technology and precise control, you can achieve the level of precision that was once unimaginable. Not only does this enhance the overall quality of your work, but it also opens up countless possibilities for creativity and innovation.

Now, let’s move on to the next section and explore the world of plasma laser cutting machines.

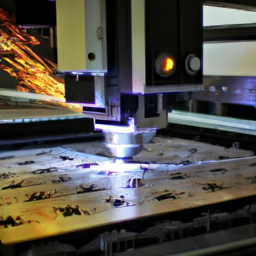

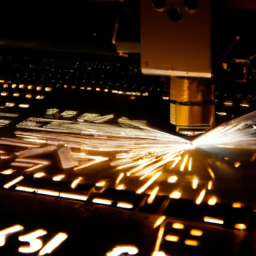

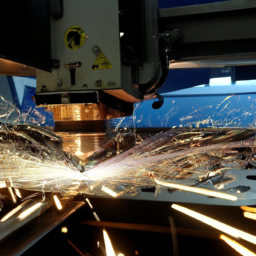

Plasma Laser Cutting Machine

If you’re looking for a laser cutting machine that can handle thick materials, a plasma laser cutting machine is a great choice. It’s a cost-effective option for large-scale projects, making it a popular choice among manufacturers and fabricators.

With its powerful plasma arc, this machine can effortlessly cut through materials like steel and aluminum with ease. Not only that, but it also boasts fast cutting speeds, allowing you to complete your projects in a fraction of the time compared to other methods.

Plus, it’s a cost-effective option for large-scale projects, making it a popular choice among manufacturers and fabricators.

Suitable for thick materials

One interesting statistic to consider is that these laser cutting machines are capable of cutting through thick materials with precision. This makes them highly suitable for heavy-duty applications that require the cutting of thick materials. Here are some key features that contribute to their thick material compatibility:

- High power laser: These machines are equipped with high power lasers that can easily penetrate and cut through thick materials.

- Adjustable focal length: The focal length can be adjusted to optimize the cutting performance for different thicknesses of materials.

- Superior beam quality: The lasers used in these machines have excellent beam quality, ensuring precise and clean cuts even in thick materials.

- Advanced control systems: These machines are equipped with advanced control systems that allow for precise control over the cutting process.

With their ability to handle thick materials, these laser cutting machines also offer fast cutting speeds, making them a versatile and efficient tool for various applications.

Fast cutting speeds

You’ll love how quickly these machines can cut through materials! With their fast cutting speeds, you can achieve high cutting accuracy in no time. Whether you’re working with metal, wood, or plastic, these subtractive laser cutting machines are versatile and can handle a wide range of materials. They are designed to deliver precise and clean cuts, ensuring that your projects turn out exactly as you envision them.

Not only do these machines offer fast cutting speeds, but they also provide excellent edge quality, minimizing the need for additional finishing work. As we move into the next section, you’ll discover how these machines are not only fast and accurate but also cost-effective for large-scale projects.

Cost-effective for large-scale projects

If you thought fast cutting speeds were impressive, wait until you hear about the cost-effective solutions offered by these top 10 subtractive laser cutting machines. Not only do they deliver precise cuts, but they also prove to be efficient for large-scale projects.

With their advanced technology and high-powered lasers, these machines ensure efficient production without compromising on quality. They are designed to handle the demands of big projects while keeping costs in check.

By offering a cost-effective approach to precision cutting, these machines enable businesses to save on both time and money, making them an ideal choice for those looking to optimize their operations.

And now, as we move towards the next section about waterjet cutting machines, get ready to explore another innovative method of precision cutting.

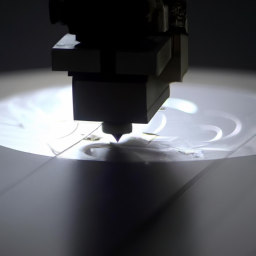

Waterjet Cutting Machine

Prepare to be amazed by the waterjet cutting machine, where a powerful stream of water mixed with abrasive particles is ready to slice through any material with the precision of a surgeon and the force of a hurricane.

Here are five reasons why the waterjet cutting machine is a game-changer:

-

Versatility: The waterjet cutting machine can handle metal, stone, glass, or even food, making it perfect for a wide range of applications.

-

No heat affected zone: Waterjet cutting doesn’t produce any heat, minimizing the risk of warping or damaging the material being cut.

-

High precision: The waterjet cutting machine can cut with a tolerance as low as 0.1 mm, ensuring accurate and clean cuts.

-

Environmentally friendly: Waterjet cutting is a sustainable and eco-friendly cutting method as it doesn’t use any chemicals or produce any hazardous waste.

-

Cost-effective: Waterjet cutting reduces material waste and requires minimal secondary finishing, making it cost-effective for large-scale projects.

The waterjet cutting machine is revolutionizing precision cutting, offering a wide range of advantages and applications.

Frequently Asked Questions

Can laser cutting machines be used on all types of materials?

Yes, laser cutting machines have several advantages. They can be used on a wide range of materials, including metals, plastics, wood, and fabrics. They offer precise and clean cuts, allowing for intricate designs.

However, there are some limitations. Laser cutting machines may struggle with highly reflective materials like copper or aluminum. Additionally, certain materials may release toxic fumes when cut, requiring proper ventilation.

Overall, laser cutting machines are versatile and efficient tools for various applications.

What safety precautions should be taken when operating a laser cutting machine?

When operating a laser cutting machine, it’s crucial to prioritize safety precautions. For instance, an employee at a manufacturing plant suffered a serious eye injury when proper safety goggles weren’t worn. To avoid such incidents, always wear appropriate protective gear, such as safety glasses and gloves.

Additionally, thorough training for laser cutting machine operation is necessary to ensure a safe working environment. Remember, laser cutting machine safety precautions are vital for preventing accidents and maintaining worker well-being.

How often do laser cutting machines require maintenance or servicing?

Laser cutting machines require regular maintenance and servicing to ensure optimal performance. Common issues during maintenance include laser tube degradation, mirror misalignment, and lens contamination. Regular cleaning of the machine and checking for any loose connections is essential.

Advantages of laser cutting machines include high precision, fast cutting speed, and versatility. However, disadvantages include high initial cost and the need for trained operators.

Overall, proper maintenance is crucial to keep laser cutting machines running smoothly.

What is the maximum thickness of material that can be cut using a laser cutting machine?

The maximum cutting capacity of a laser cutting machine depends on several factors. These include the power of the laser, the type of material being cut, and the focal length of the lens.

Generally, laser cutting machines can cut materials up to a certain thickness, which varies from machine to machine. It is important to consider these factors and consult the machine’s specifications to determine the maximum thickness of material that can be cut.

Are laser cutting machines suitable for both small-scale and large-scale production?

Laser cutting machines are suitable for both small-scale and large-scale production. In small-scale production, the benefits of using laser cutting machines include precise and intricate cuts, allowing for the creation of complex designs. This improves the overall quality of the end product.

In large-scale production, laser cutting machines can significantly improve efficiency by automating the cutting process, reducing labor costs, and increasing productivity. This makes them ideal for mass production and meeting tight deadlines.

Conclusion

So there you have it, the top 10 subtractive laser cutting machines for precision cutting. Whether you’re in need of a fiber laser, CO2 laser, YAG laser, UV laser, plasma laser, or waterjet cutting machine, this list has got you covered.

Each machine is designed to provide precise and accurate cuts, ensuring that your projects are completed with the utmost precision. Just like a skilled surgeon with a scalpel, these machines slice through materials effortlessly, like a hot knife through butter.